categories

recent posts

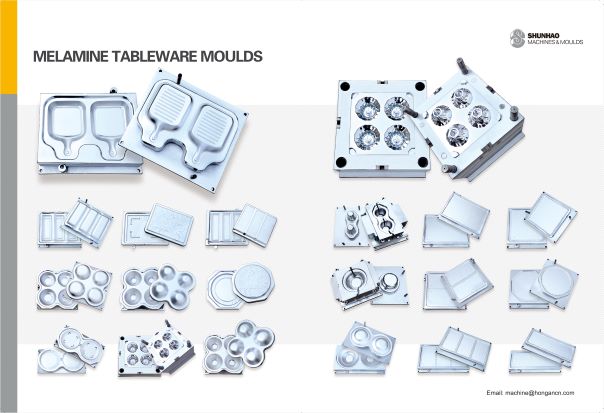

Shunhao moulds factory can make molds: 1. Melamine crockery moulds 2. Urea crockery moulds 3. Glossy melamine moulds 4. Matt finished melamine moulds ...

Shunhao factory has been serving the machines and molds to melamine tableware factories, urea tableware factories, UF toilet seat and cover factories ...

Rice husk tableware Introduction: Rice husk tableware is to regenerate this discarded rice husk into natural, healthy and free of any harmful chemical...

Rationally view the harm of melamine tableware 1) What is melamine tableware Melamine tableware is made from melamine powder (known in the industry as...

Precautions and cleaning of melamine tableware 1. Main ingredients of melamine tableware raw materials: 100% melamine (domestically called A5 material...

The advantages and disadvantages of melamine tableware In daily life, there are many meals used. Tableware is divided into ceramic tableware, bone chi...

Introduction to Chinese plant fiber

Plant fibres are thick-walled tissues that are widely distributed in seed plants. Its cells are slender, sharp at both ends, have thick secondary walls, often have single-grained holes on the walls, and generally have no living protoplasts when mature. Plant fiber is a filamentous or floc formed by the combination of cellulose and various nutrients. It has the functions of supporting, connecting, wrapping, filling, etc., and is widely distributed in stems, roots, fruits and shells of plants.

In plant stems, such as ramie, hemp, flax and jute herbaceous stems, with a particularly developed bast fiber bundle, a variety of textiles can be used. These fibers have no or little lignification and are called soft fibers. In some woody stems, the toughness fibers are also well developed. They are excellent raw materials for making special papers, such as mulberry trees, mulberry trees, and green sandalwood. Leaf fiber mainly exists in the veins of monocotyledonous plants. The cell wall is highly lignified and hard, called hard fiber. These fibers have large tensile strength and strong corrosion resistance, and are mainly used for making ropes or for spinning, such as sisal and abaca.

There are generally fewer fibers in the roots, but some of the fibers in the roots of the plants can also be used, such as horseshoe. In addition, the peels of some plant fruits contain fibers, such as coconuts, or fiber hairs with special uses, such as gebe. Seed surface growth

Prominent examples are cotton fibers, others such as kapok, willow and other seed surfaces, as well as fibers.

Types of

According to the different distribution positions in the plant body, it can be roughly divided into two categories: xylem outer fibers and xylem fibers. Wood fiber type structure xylem fibers, including bast fibers, cortical fibers, and fibers surrounding the vascular bundle. Such fibers are generally long-spindle shaped, with sharp ends and some ends forming a blunt bifurcation. The cell wall is thicker and smaller than the cell lumen. Cell walls are either woodized at all or completely lignified, and nascent fibers are usually longer than secondary fibers.

Xylem fibers, also known as wood fibers, have a lignified secondary wall. The shape of the cells is usually sharp at both ends, but there are variations in various shapes and pits. This type of fiber is one of the important constituents of wood.

Wood fiber can be divided into two types: 1 fiber tracheid, which is gradually played by the tracheid (see xylem)

From the beginning, there are obvious margins on the cell wall. 2 tough fiber, as a result of the further evolution of the fiber tracheid, the cell wall is thicker, and the pits on the wall are degenerated into single-grained holes, which are also called wood fibers. In the wood of some angiosperms (such as eucalyptus), a series of transitions between the fibers and the tracheids can be seen, that is, the thickness of the cell wall is gradually increased, the length is shortened, and the marginal pores on the wall are gradually reduced to a single Pore and so on. Both the fiber tracheid and the tough fiber may have a lateral partition, which is specifically referred to as a dividing fiber. Many plants have this structure, such as the genus Vitis and Hypericum. These separator fibers retain protoplasts for a long time and have the function of storing starch, oil and resin.

kind

Seed fiber: refers to the single cell fiber that some plant seed epidermal cells grow. Such as cotton, kapok.

Bast fiber: A single fiber or process fiber obtained from some plant phloem. Such as: linen, ramie, jute, bamboo fiber.

Leaf fiber: A process fiber obtained from the leaves or sheaths of some plants. Such as: sisal, abaca.

Fruit fiber: A fiber obtained from the fruits of some plants. Such as: coconut fiber.

development

Plant fibers are formed by different meristems. The fibers of the xylem and the phloem are derived from the original formation or formation layer. Some fibers can be produced by basic meristems, which cells that develop into fibers in the future stop the lateral division long before, but only longitudinally. The fibers in the vascular bundle sheath may be partially formed by the original formation layer and the other portion formed by the basic meristem.

Primary fibers occur before the organ is stretched, and they continue to extend to considerable lengths while the surrounding cells are still dividing. For example, the bast fiber of ramie can continue to stretch for several months, and the final length is increased by 4, 50,000 times and up to 55 cm. The elongation of such cells, in addition to growth (co-growth) with surrounding cells; and the growth of the cell tip into the surrounding cells (invasive growth). After the fiber of the ramie stops elongating, the base of the fiber may also have thick secondary walls when secondary wall deposition occurs. But there is still life content and thin cell walls at the top, so the cell tip can continue to stretch.

Cotton fiber is the stretched part of epidermal cells on cotton ovules. Its development process is: when the cotton ovule is fertilized, the hair-producing cells that produce fibers on the epidermal layer of the ovule rapidly elongate. Thereafter, the cell wall is also gradually thickened, that is, the secondary wall containing cellulose is continuously deposited in the primary wall. When the seeds are mature, the original tubular fiber cells are dried and flattened, and twisted, and the remaining protoplasts in the cell wall are also dried and deposited. After the cotton boll is cracked, the fiber cells die and become silver-white cotton fibers.

Plant fiber environmental protection material

effect

The degradable plant fiber flowerpot uses plant fiber as the main raw material, and its gas permeability is very good, which is beneficial to the growth of flowers. The ability of fiber flowerpots to absorb solar infrared rays during the day is very strong. This is not possible with other types of flowerpots. The ability to absorb infrared rays is strong, and the temperature of flowerpots will increase. In cold winters, the use of such flowerpots is more beneficial. Plants grow and can protect plants safely for the winter.

The plant fiber itself has some nutrients needed for flower growth. During the process of plant growth, the nutrients contained in the plant can be slowly released into the soil for plant growth. Fiber flower pots are made from plant fibers and do not cause any harm to the body. And after the flower pot is broken, it can be degraded without polluting the environment. There are a variety of flower pots on the flower market, including wooden flower pots, clay pots, ceramics and plastic flower pots. The wooden flowerpot is light, but there is no colorful color; the mud flowerpot has good air permeability, but it is not beautiful and heavy, the ceramic flowerpot is beautiful and gorgeous, but it is fragile and high in price. The plastic flowerpot is light and beautiful, but the air permeability is good. Not good, plants are prone to rotten roots, and plastics cannot be disposed of to pollute the environment. Plant fiber pots are the best choice.

Material description

Plant fiber environmental protection material is made of rice straw, straw, wheat straw, corn stover, cotton stalk, sawdust, bamboo shavings and other crop straws or other plant stems, first made of 10 ~ 200 mesh plant fiber powder, and then made by special technology A new environmentally friendly material that is mixed with raw materials and then molded or injection molded; natural ingredients can reach 60~90%; can be made into disposable catering containers, controlled degradation containers, handicrafts, daily necessities, building boards, industrial packaging, etc. article. Characteristics of raw materials: Plant fiber environmental protection materials are derived from crop straws and fast-recycled plants, which are plant fiber flower pots.

Inexhaustible renewable resources in nature; it is the development and utilization of waste or resources that are not useful, and it is a waste of resources. Features of the product: Plant fiber environmental protection material has high strength, natural and simple surface texture, bright color and novel texture. It is suitable for many times and repeated use. It can replace some plastic, glass, pottery, porcelain and other products to save oil resources. And energy consumption.

Development History

A large amount of garbage is non-degradable waste, causing serious pollution to the ecological environment and endangering people's health. The natural content of plant fiber environmental protection materials can reach more than 80%, and the finished articles can be naturally degraded after being discarded in the natural environment. It is a new type of green environmental protection material.

The original product of plant fiber environmental protection products is disposable tableware, which was developed for the treatment of “white pollution”. Around 2000, it formed a disposable catering container with hot tableware, cold tableware, supermarket fresh tray, spoon, chopsticks, etc. product. In the development of disposable catering containers, the materials developed have high strength, natural and simple surface texture, can be colored in a variety of bright colors, and are more suitable for making multiple, repeated use items. On this basis, controlled degradable containers, daily necessities, handicrafts, industrial packaging, etc. were developed around 2003.

Intellectual property specializing in plant fiber research and development has been in existence for more than ten years. In this field, formula technology and production technology are at the domestic leading level. At the same time, plant fiber environmental protection product technology belongs to Chinese original technology and is at the leading level in the world.

Characteristics

1. Utilization of renewable resources

The plant fiber environmental protection material is derived from crop straw and fast-recycling plants. It is an inexhaustible renewable resource in nature. It is a waste resource or a resource that is of little use. It is a waste of resources. .

On the earth, green plants use solar energy for photosynthesis, providing 155 billion tons of dry matter per year, which can fix 500 billion tons of organic carbon, which is 20 times the total amount of oil, coal and natural gas. It has the most abundant biological resources, can proliferate year after year, and has strong regenerative nature. This is a kind of renewable and inexhaustible renewable resource that nature gives us.

2. Finished products can replace some plastic, ceramic, porcelain, glass products

The plant fiber environmental protection material has high strength, natural surface texture, simple color, bright color and novel texture. It is suitable for many times and repeated use. After nearly ten years of research and development, the products can replace some plastic, glass and ceramics. , porcelain and other products.

Products made from plant fiber environmentally friendly materials can replace some plastic products and save valuable petroleum resources. The raw materials for most synthetic polymers are oil and coal, but the total oil reserves in the world are more than 80 billion cubic meters, and more than 3 billion cubic meters are consumed each year. It is expected that it will take less than a few decades and the oil resources on the earth will be consumed. After all, the storage of coal is more than a hundred years. Every year, more than 140 million tons of plastics are synthesized from petroleum in the world. The output of our country is about 8 million tons. As long as 1% of the products are replaced with plant fiber environmentally friendly materials, it can form a huge industry.

3. Biodegradable

A large amount of plastic waste is non-degradable waste, causing serious pollution to the ecological environment and endangering people's health. The natural content of plant fiber environmental protection materials can reach 60-90%. The finished articles can be naturally degraded after being discarded in the natural environment. The materials are derived from natural resources. After being processed into materials, they can be returned to nature after being used by humans. An environmentally friendly material, a new type of green material.

Using its degradable properties, it can be used to make seedling cups and transplanting pots for 1-3 months, 4-6 months for ornamental pots, and 2-3 years for ordinary pots. [2]

the difference

Plant fiber and dietary fiber

Plant fiber is a substance that cannot be digested and includes cellulose, hemicellulose, lignin, pectin, gums and some non-cellulosic sugars. Dietary fiber is a plant fiber that is edible by humans. The basic substance constituting the plant fiber is cellulose, which is a polymer in which 7,000 to 10,000 glucose molecules are arranged in parallel in a bundle and are linked by a glycoside chain.

Plant fiber is a filamentous or floc formed by the combination of cellulose and various nutrients, which has the functions of supporting, connecting, wrapping, filling and the like. Due to the different nutrients, linkages and attachment sites of cellulose, plant fibers can have many different characteristics, and their morphology and tissue structure change significantly with the growth and maturity of plants. At the maturity of the plant, the plant fibers have been gelatinized, keratinized, and lignified. At this time, the plant fiber is insoluble in water and cannot be decomposed by human digestive enzymes, which is called crude fiber. For example, the bud and the flowering loofah are rich in digestible fiber, which is a delicious food for people. The fiber of eucalyptus is mature and aging, so it is inedible and can only be used for papermaking. The mature loofah is also grown. Inedible, loofah is often used as a dishwashing device. It should be pointed out that whether it is digestible fiber or non-digestible crude fiber, its lipid-lowering function is unique and it is an important and irreplaceable food for human beings.

Plant fiber and animal fiber

Plant fiber is also called natural cellulose fiber, and its main constituent material is cellulose. The important plant fibers in international trade are: cotton, hemp, jute, flax, abaca, sisal, henaquina and coir. According to the plant parts of the fiber, the plant fibers are further divided into seed fibers, fruit fibers, bast fibers, stem fibers and leaf fibers.

Animal fibers are divided into three categories: animal hair and fluff, poultry down and feathers, silk, the main source is artificially reared animals. Animal fibers are also known as protein fibers because their main constituent is protein. There are many types of animal hair, the most important being sheep wool, referred to as wool. Wool is widely used in the manufacture of various textiles and also in felting. In addition to wool, there are cashmere, rabbit hair, camel hair, yak hair and so on. Animal hair other than wool, sometimes referred to as special animal hair, is also used to make textiles, which can be purely spun or blended with other fibers. In blends, the warmth and feel of the fabric can be improved by using their unique gloss, fineness and softness. The down and feathers of poultry can be blended with other fibers in textiles, and can also be used as filling materials such as duck down, goose down and so on. Silk is the glandular secretion of silkworm, which has silkworm, tussah silk, ramie silk and potato silk. Animal fiber has strong hygroscopicity, good warmth retention, good elasticity, easy to stain, soft gloss, good dyeing, unique fluffing, excellent quality, natural wavy curl, and can be used to make wool and wool. , felts, felts and other domestic and industrial products, wool fiber is a high-grade textile fiber

300TONS Single Color Hydraulic Press Melamine Tableware Dinner Set Making Moulding Machine

300TONS Single Color Hydraulic Press Melamine Tableware Dinner Set Making Moulding Machine

Our machine is Suitable for urea tableware, melamine dinnerware.

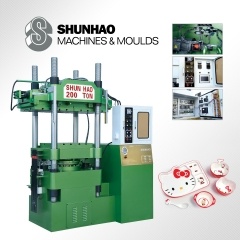

200TONS Automatic Single Color Melamine Tableware Molding Machine

200TONS Automatic Single Color Melamine Tableware Molding Machine

Suitable to be used in the molding operation of urea tableware, melamine tableware

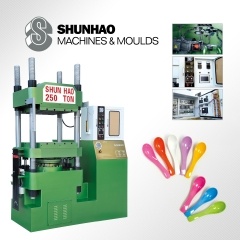

3Year Warantee 250TON Singal Color Melamine Tableware Molding Machine

3Year Warantee 250TON Singal Color Melamine Tableware Molding Machine

Our machine is suitable for all kind of Melamine Dinnerware,plate ,bowl ,tray ,glass ,mug

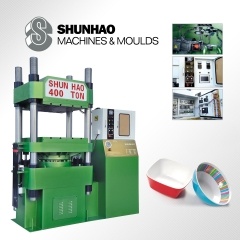

400TON Automatic Melamine Crockery Molding Machine With Singal Color

400TON Automatic Melamine Crockery Molding Machine With Singal Color

Our Machine is special in Melamine Crockery ,like bowl ,plate ,tray ,mug ,glass.

500ton Melamine Crockery Molding Machine With Plc Control

500ton Melamine Crockery Molding Machine With Plc Control

500ton Melamine Crockery Molding Machine With Plc Control For Melamine Tableware ,Melamine Crockery

200Ton 2Color Melamine Tableware Automatic Molding Machine

200Ton 2Color Melamine Tableware Automatic Molding Machine

This machins is Suitable for producing double color melamine tableware, toilet seat cover, Bakelite switches, and mahjong.

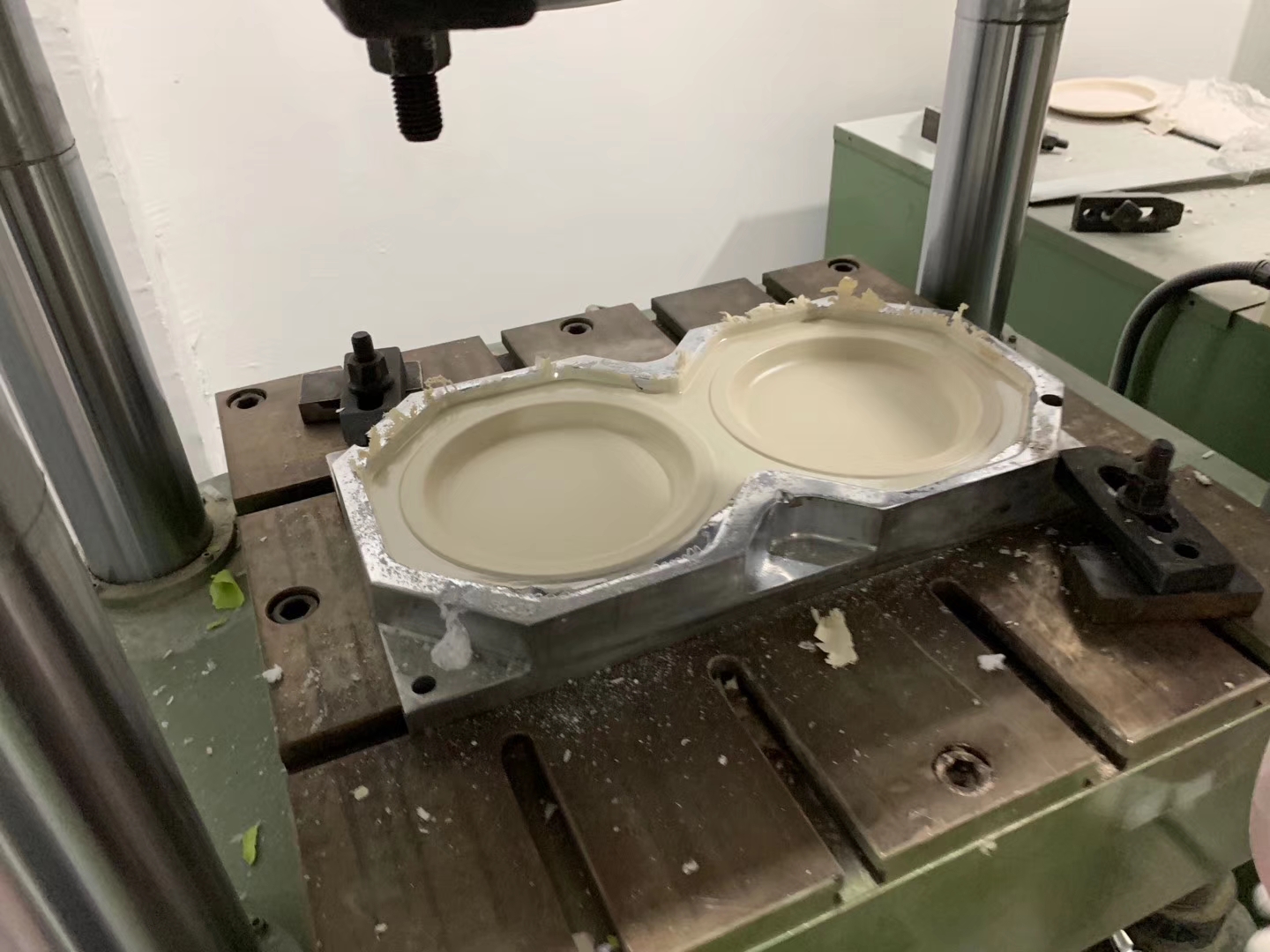

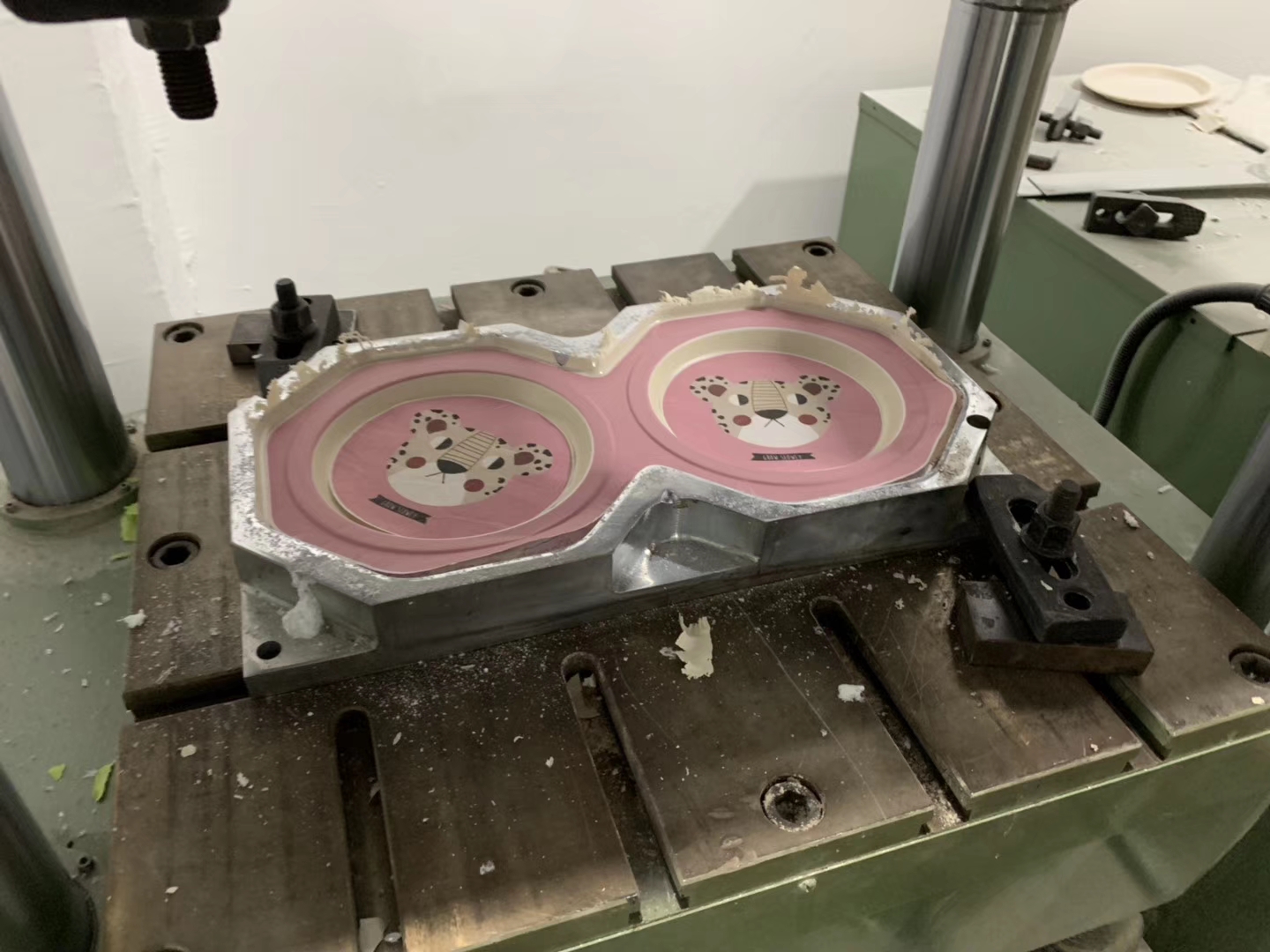

Workshop Show

Workshop Show

Products Show

Products Show

Video Show

Video Show

OUR CERTIFICATES

OUR CERTIFICATES

the professional team to service !