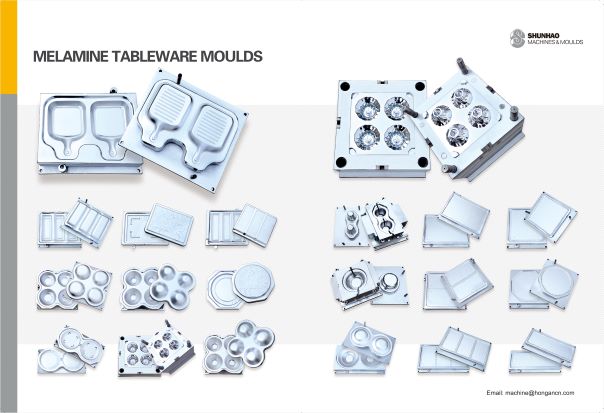

Shunhao moulds factory can make molds: 1. Melamine crockery moulds 2. Urea crockery moulds 3. Glossy melamine moulds 4. Matt finished melamine moulds ...

Shunhao factory has been serving the machines and molds to melamine tableware factories, urea tableware factories, UF toilet seat and cover factories ...

Rice husk tableware Introduction: Rice husk tableware is to regenerate this discarded rice husk into natural, healthy and free of any harmful chemical...

Rationally view the harm of melamine tableware 1) What is melamine tableware Melamine tableware is made from melamine powder (known in the industry as...

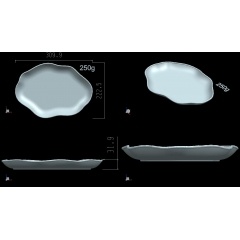

item no.:

SH-0998lead time:

20DAYSproduct orgin:

CHINAbrand:

Customizedshipping port:

XIANMEN SEA PORTpayment:

TT/LCMOQ:

1

| Steel Grade | S50C | P20 | P20HH | 718H | H13 | 2738 | 2311 | NAK80 |

| Hardness | 17-22 | 27-30 | 33-37 | 33-38 | 45-50 | 36-40 | 28-32 | 34-40 |

| 1.R&D | RFQ Inquire According to samples , pictures with dimension , drawings and specific requirements . |

| 2.Communication | Mold steel , cavity number , kind of runner Compress data , mold details , delivery time , payment item and etc. |

| 3.Place an order | Sign contract & advance payment |

| 4. Mould Design | 1] Product and Mold 2D & 3D design based on all of customer’s requirements |

| 2] Send to customers for inspection. | |

| 3] If some structure is not perfect or can not be done on the molding.We will send good suggestion to customers. | |

| 5.Mold Tooling | Start to Cut steel , CNC machining , EDM , polishing and testing after mold design confirmed . |

| 6.Mold Processing | Send mold process schedule with photos update to customers each week . |

| 7. Mold Testing | 1]Customer come to our factory inspection mold trial if they are free |

| 2] we checking the dimension ,weight , wall thickness and arrange send actual samples to customers by courier . | |

| 8. Mold Modification | Modification the mold according to customer’s feedback . |

| 9. Packaging and | Once sample approved , Packing mold properly and prepare all of mold spare parts packing with mold together. |

| Delivery |

According to FOB or CIF(CFR) to shipping molds.

|

prev :

High Quality Cooking Ware Moldnext :

China Manufacturer Professional Custom High Quality Melamine Dinnerware Mold Melamine Crockery Mould-Matte Finish

Melamine Crockery Mould-Matte Finish

China's most advanced production technology, the most experienced melamine tableware mold manufacturers

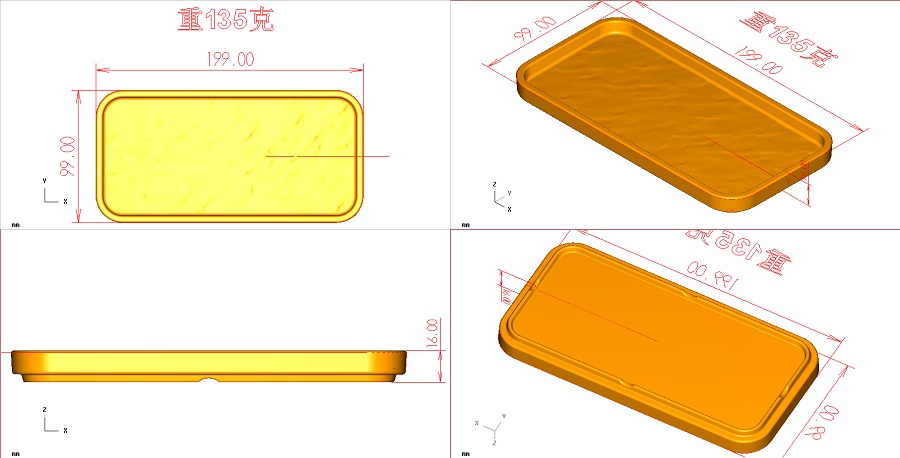

Melamine Plate Mold Matte-Finished With 1 Cavity

Melamine Plate Mold Matte-Finished With 1 Cavity

Production Melamine Tableware Mould Within 20 Days In China! Custom Mould Making Experience 15 Years!

Melamine Bowl Mold Matte-Finished-3"small bowl with 6cavity

Melamine Bowl Mold Matte-Finished-3"small bowl with 6cavity

SHUNHAO Company Is A Professional Melamine Mold Supplier Melamine Mould Manufacturing, Melamine Crockery Molding Machine And Accessory For Customers.

Melamine Bowl Mould Matte-Finished-3.5"small bowl with 6 cavity

Melamine Bowl Mould Matte-Finished-3.5"small bowl with 6 cavity

Specialized In melamine tableware mold making&molding,Custom melamine tableware mould making, Don't miss it.

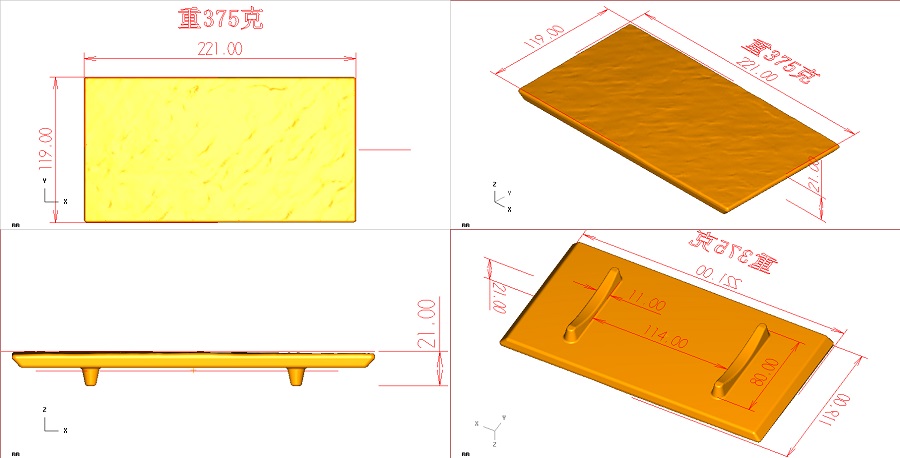

Melamine Plate Mold Matte-Finished-10"plate with 2 cavity

Melamine Plate Mold Matte-Finished-10"plate with 2 cavity

Melamine Plate Molds with Matte-Finished effect, can help you to get good feedback of products selling. We have qualified experience in making such kinds of Melamine Molds with Matt Finished.

Melamine Plate Mold Matte-Finished-12"plate with 2cavity

Melamine Plate Mold Matte-Finished-12"plate with 2cavity

Melamine Plate Moulds with Matte-Finished effect, can help you to get good feedback of products selling. We have qualified experience in making such kinds of Melamine Molds with Matt Finished.

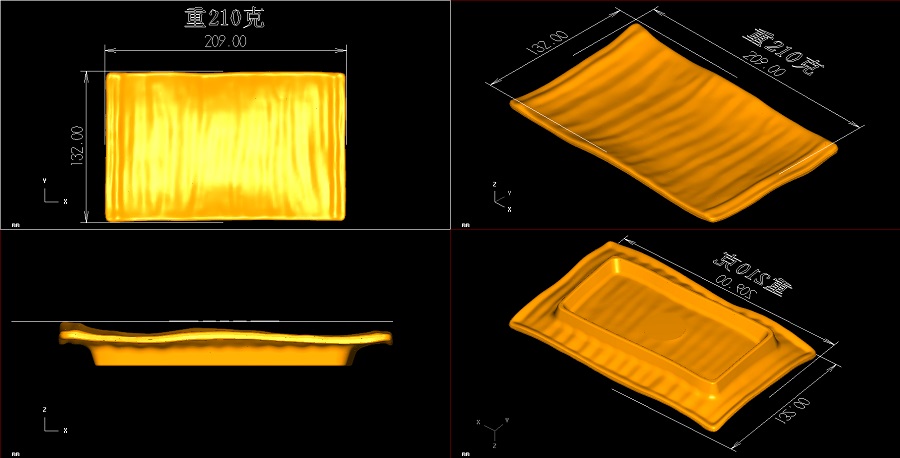

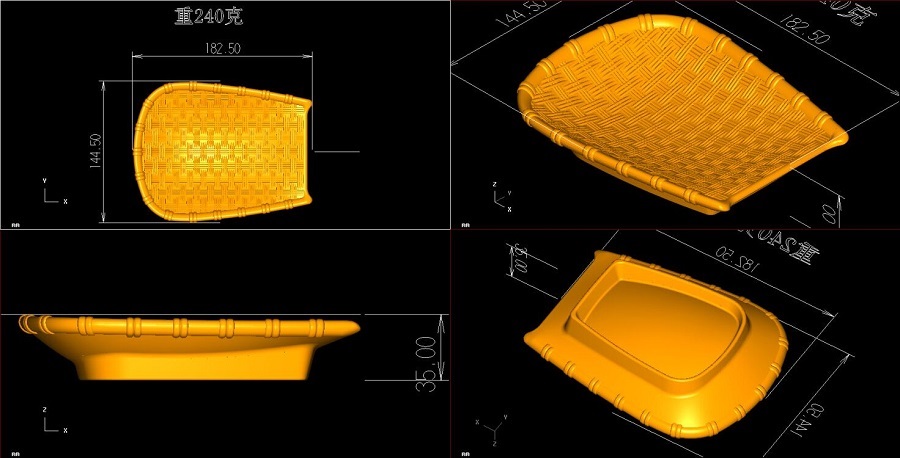

Melamine Dish Mould Matt With Bamboo Design

Melamine Dish Mould Matt With Bamboo Design

We're specilized in OEM Custom Melamine compression mould/Custom made Melamine compression mold maker

Workshop Show

Workshop Show

Products Show

Products Show

Video Show

Video Show

OUR CERTIFICATES

OUR CERTIFICATES

the professional team to service !