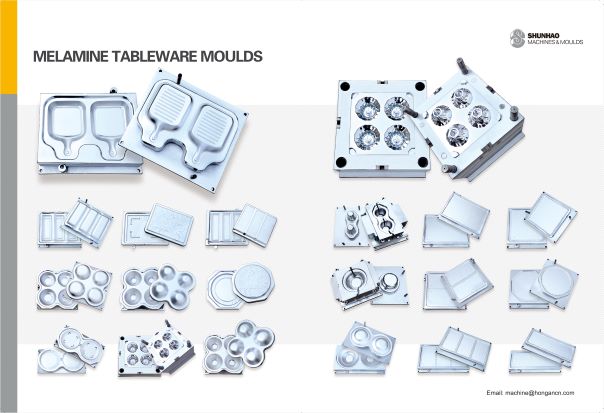

Shunhao moulds factory can make molds: 1. Melamine crockery moulds 2. Urea crockery moulds 3. Glossy melamine moulds 4. Matt finished melamine moulds ...

Shunhao factory has been serving the machines and molds to melamine tableware factories, urea tableware factories, UF toilet seat and cover factories ...

Rice husk tableware Introduction: Rice husk tableware is to regenerate this discarded rice husk into natural, healthy and free of any harmful chemical...

Rationally view the harm of melamine tableware 1) What is melamine tableware Melamine tableware is made from melamine powder (known in the industry as...

item no.:

SHW6666lead time:

90DAYSproduct orgin:

CHINAbrand:

Shunhaoshipping port:

XIANMEN SEA PORTpayment:

TT/LCcolor:

WhiteMOQ:

1

|

Items

|

Capacity,300dyas/24hours

|

Installed powder

|

Area

|

Steam consumption

|

Actual power consumption

|

|

UMC LINE

|

6000T

|

419.25

|

700

|

1.5

|

250kwh

|

|

MMC LINE

|

6000T

|

445.75

|

800

|

1.2

|

350-450KWH

|

|

LG

|

2000T

|

168.6

|

500

|

1.3

|

110KWH

|

|

MODEL NO

|

Volume

|

Chemicals

|

Heating channels

|

Material

|

Power(kw)

|

Negative pressure system

|

|

SHF-1000

|

1000L

|

Urea formaldehyde resin

|

External coils

|

CS,SS304

|

3

|

Sucking machine condenser

|

|

SHF-1600

|

1600L

|

Urea/melamine formaldehyde resin

|

Internal&external coils

|

CS,SS304

|

4

|

Sucking machine condenser

|

|

SHF-3100

|

3100L

|

Urea formaldehyde resin

|

Internal&external coils

|

CS,SS304

|

5.5

|

Sucking machine condenser

|

|

SHF-4000

|

4000L

|

Urea formaldehyde resin

|

Internal&external coils

|

CS,SS304

|

7.5

|

Sucking machine condenser

|

|

SHF-5000

|

5000L

|

Urea formaldehyde resin

|

Internal&external coils

|

CS,SS304

|

11

|

Sucking machine condenser

|

|

Model

|

Volume

|

Products

|

Material

|

Power(kw)

|

Transfer

|

Heating

|

Dehydration

|

|

SHN-500

|

500L

|

UMC

|

304CS,SS304

|

7.5

|

Turn over the cylinder

|

Steam/oil

|

Sucking machine

|

|

SHN-1500

|

1500L

|

UMC

|

304CS,SS304

|

18.5

|

Turn over the cylinder

|

Steam/oil

|

Sucking machine

|

|

SHN-2000

|

2000L

|

UMC/MMC

|

304CS,SS304

|

22

|

Turn over the cylinder

|

Steam/oil

|

Sucking machine vacuum dehydration

|

|

SHN-2900

|

2900L

|

UMC/MMC

|

304CS,SS304

|

30

|

Turn over the cylinder

|

Steam/oil

|

Sucking machine vacuum dehydration

|

|

SHN-4800

|

4800L

|

UMC/MMC

|

304CS,SS304

|

45

|

Turn over the cylinder

|

Steam/oil

|

Sucking machine vacuum dehydration

|

|

Model

|

Volume

|

Products

|

Material

|

Powder

|

Transfer

|

Drive system

|

|

SLD-4000

|

4000L

|

UMC/MMC

|

CS,SS304

|

5.5

|

Belt/swinging spiral

|

Frequency control

|

|

SLD-5000

|

5000L

|

UMC/MMC

|

CS,SS304

|

7.5

|

Belt/swinging spiral

|

Frequency control

|

|

Model

|

Capacity

|

Finished product

|

Heat Radiation

|

Turn-over times

|

Belt width(m)

|

Power(kw)

|

|

SLH-1.5*25

|

250-350

|

LG

|

450

|

1

|

1.5

|

40

|

|

SLH-1.5*31

|

350-450

|

LG/UMC

|

500

|

2

|

1.5

|

48

|

|

SLH-2*37

|

500-550

|

UMC

|

650

|

2

|

2

|

55

|

|

SLH-2*35

|

750-850

|

UMC

|

900

|

2

|

2

|

90

|

|

SLH-2*38

|

900-970

|

UMC

|

1000

|

2

|

2

|

113

|

|

SLH-2*43

|

700*750

|

UMC/MMC

|

800

|

3

|

2

|

70

|

|

SLH-2*45

|

750-850

|

UMC/MMC

|

1000

|

3

|

2

|

75

|

|

SLH-2*47

|

1100-1400

|

UMC/MMC

|

1350

|

3

|

2

|

118

|

|

SLH-2.2*41

|

1200-1300

|

MMC

|

1100

|

3

|

2

|

75

|

|

Model

|

Products

|

Material

|

Operation principle

|

Cleaning

|

|

Dia400-A

|

Powders

|

Ss304

|

Tunbine crushing

|

Dust collection bags

|

|

Dia400-B

|

Granules

|

Ss304

|

Tunbine crushing

|

Dust collection bags

|

|

Model

|

Loading capacity

|

Grinding

|

Material

|

Power(KW)

|

Gearbox

|

Transmission form

|

|

Dia2300*2500

|

2000-2300

|

40CM92 porcelain ball plate / 95 porcelain

ball

|

Carbon steel

|

45KW with frequency conversion

|

ZLY224-6.3

|

gear

|

|

Dia2000*2500

|

1800-2000

|

40CM92 porcelain ball plate / 95 porcelain

ball

|

Carbon steel

|

30KW with frequency conversion

|

ZLY200-6.3

|

gear

|

|

Dia2000*2250

|

1500-1800

|

40CM92 porcelain ball plate / 95 porcelain

ball

|

Carbon steel

|

30KW with frequency conversion

|

ZLY200-6.3

|

gear

|

|

Dia1960*1960

|

1100-1300

|

40CM92 porcelain ball plate / 95 porcelain

ball

|

Carbon steel

|

22KW with frequency conversion

|

ZLY200-6.3

|

gear

|

|

Dia1660*1800

|

800-1000

|

40CM92 porcelain ball plate / 95 porcelain

ball

|

Carbon steel

|

22KW with frequency conversion

|

ZLY200-6.3

|

gear

|

|

Dia2100*2500

|

1500

|

40CM92 porcelain ball plate / 95 porcelain

ball

|

Carbon steel

|

30KW with frequency conversion

|

ZLY200-6.3

|

gear

|

|

Model

|

Meshs

|

Layers

|

Diameter

|

Products

|

Material

|

Power

|

|

SLZ-1200

|

20-80

|

2-3

|

DIA1150

|

UMC/MMC/LG

|

304

|

1.1

|

|

SLZ-1500

|

20-80

|

2-3

|

DIA1450

|

304

|

1.5

|

|

Model

|

Size

|

products

|

Capacity

|

Marerials

|

Power(kw)

|

|

SLZ-3

|

Dia200-2500mm

|

Umc/mmc

|

1t/h

|

304

|

1.1

|

|

SLZ-6

|

Dia-400-6000mm

|

Umc/mmc

|

1t/h

|

304

|

1.5

|

|

SLZ-8

|

Dia200-1500mm

|

mmc

|

1t/h

|

304

|

2.25

|

|

Model

|

Cpapcity

|

Products

|

Material

|

Power(kw)

|

Transfer

|

|

SLS-4

|

1t/h

|

MMC

|

SS304

|

4

|

Turn over cylinder

|

UMC Powder Production Complete Line Machines Supplier

UMC Powder Production Complete Line Machines Supplier

Supplying the complete production line machines for UMC / MMC powder Professional manufacturing and Responsible service.

UF/MF Molding Compound Plant Machine Supplier

UF/MF Molding Compound Plant Machine Supplier

We are the manufacture of UF/MF Molding Compound Plant Machine

Urea formaldehyde molding compound machine manufacturer

Urea formaldehyde molding compound machine manufacturer

we are the Urea formaldehyde molding compound machine manufacturer

Good Quality Melamine Resin plant machine Manufacture

Good Quality Melamine Resin plant machine Manufacture

We are the maker of Melamine Resin plant machine

Good Quality Urea Fomaldehyde resin processing equipment

Good Quality Urea Fomaldehyde resin processing equipment

We are professional manufacturer of Urea/Melamine formaldehyde molding compound plant.

New Design Urea formaldehyde molding compound machines manufacturers

New Design Urea formaldehyde molding compound machines manufacturers

We are the Urea formaldehyde molding compound machines manufacturers

Urea Formaldehyde Molding compound plant

Urea Formaldehyde Molding compound plant

we are the manufacture of Urea Formaldehyde Molding compound plant

Workshop Show

Workshop Show

Products Show

Products Show

Video Show

Video Show

OUR CERTIFICATES

OUR CERTIFICATES

the professional team to service !