categories

recent posts

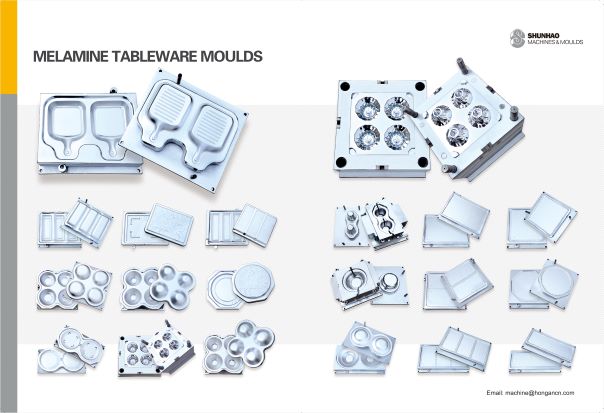

Shunhao moulds factory can make molds: 1. Melamine crockery moulds 2. Urea crockery moulds 3. Glossy melamine moulds 4. Matt finished melamine moulds ...

Shunhao factory has been serving the machines and molds to melamine tableware factories, urea tableware factories, UF toilet seat and cover factories ...

Rice husk tableware Introduction: Rice husk tableware is to regenerate this discarded rice husk into natural, healthy and free of any harmful chemical...

Rationally view the harm of melamine tableware 1) What is melamine tableware Melamine tableware is made from melamine powder (known in the industry as...

Precautions and cleaning of melamine tableware 1. Main ingredients of melamine tableware raw materials: 100% melamine (domestically called A5 material...

The advantages and disadvantages of melamine tableware In daily life, there are many meals used. Tableware is divided into ceramic tableware, bone chi...

Melamine tableware belongs to high molecular polymer, the English abbreviation is MF, and its monomers are formaldehyde and melamine. A 37% aqueous formaldehyde solution was used for the reaction, and the molar ratio of formaldehyde and melamine monomers was 2 ~ 3. Studies have shown that with the increase in the amount of formaldehyde, the combined amount of formaldehyde also increases, and the reaction is easy to proceed; by changing the amount of formaldehyde, melamine resins obtained from different methylolmelamine can be prepared. When the pH of the reaction system is 8.5, side reactions Less, the reaction is easy to control; high temperature, fast reaction speed, in the range of 54 ~ 80 ℃ has little effect on the amount of formaldehyde binding.

Melamine powder is made of melamine formaldehyde resin as raw material, cellulose as a base material, and pigments and other additives. It is a thermosetting raw material because it has a three-dimensional network structure. (The waste side cannot be returned to the furnace for production). Melamine powder scientific name melamine formaldehyde resin, simply "MF" ...

Features: Although it has melamine components, it still has the characteristics of plastic, high toxicity, high temperature resistance, dirty resistance, corrosion resistance, rough appearance, easy deformation, discoloration, and poor gloss.

Features: The appearance is almost the same as the genuine product (A5 material), but once used, the product is not resistant to dirt, easy to change color and fade, easy to deform at high temperature, and not resistant to corrosion.

Features: non-toxic and odorless, temperature resistance -30 degrees Celsius to 120 degrees Celsius, bump resistance, corrosion resistance, not only beautiful appearance, light insulation, safe use.

The raw material of tableware is Tianyuan jade porcelain powder, and its characteristics are as follows:

1. Melamine formaldehyde molding powder is odorless, tasteless and non-toxic.

2. The surface of melamine formaldehyde plastic has high hardness, luster and scratch resistance.

3. It is self-extinguishing, fireproof, impact resistant and crack resistant.

4. High temperature, high humidity stability, good solvent resistance, and good alkali resistance.

We are the manufacture of Melamine Crockery Molding Machine in China,if you need any Melamine Crockery Molding Machine ,please let me know.

prev :

Briefly describe the disinfection method of melamine tablewarenext :

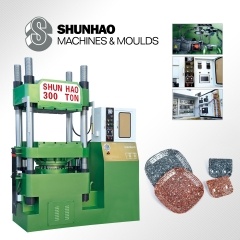

Production process of melamine tableware 300TONS Single Color Hydraulic Press Melamine Tableware Dinner Set Making Moulding Machine

300TONS Single Color Hydraulic Press Melamine Tableware Dinner Set Making Moulding Machine

Our machine is Suitable for urea tableware, melamine dinnerware.

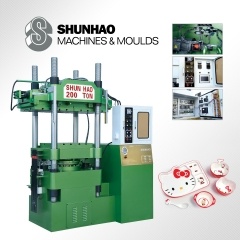

200TONS Automatic Single Color Melamine Tableware Molding Machine

200TONS Automatic Single Color Melamine Tableware Molding Machine

Suitable to be used in the molding operation of urea tableware, melamine tableware

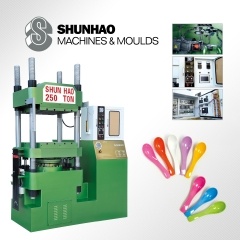

3Year Warantee 250TON Singal Color Melamine Tableware Molding Machine

3Year Warantee 250TON Singal Color Melamine Tableware Molding Machine

Our machine is suitable for all kind of Melamine Dinnerware,plate ,bowl ,tray ,glass ,mug

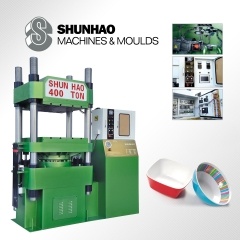

400TON Automatic Melamine Crockery Molding Machine With Singal Color

400TON Automatic Melamine Crockery Molding Machine With Singal Color

Our Machine is special in Melamine Crockery ,like bowl ,plate ,tray ,mug ,glass.

500ton Melamine Crockery Molding Machine With Plc Control

500ton Melamine Crockery Molding Machine With Plc Control

500ton Melamine Crockery Molding Machine With Plc Control For Melamine Tableware ,Melamine Crockery

200Ton 2Color Melamine Tableware Automatic Molding Machine

200Ton 2Color Melamine Tableware Automatic Molding Machine

This machins is Suitable for producing double color melamine tableware, toilet seat cover, Bakelite switches, and mahjong.

Workshop Show

Workshop Show

Products Show

Products Show

Video Show

Video Show

OUR CERTIFICATES

OUR CERTIFICATES

the professional team to service !