categories

recent posts

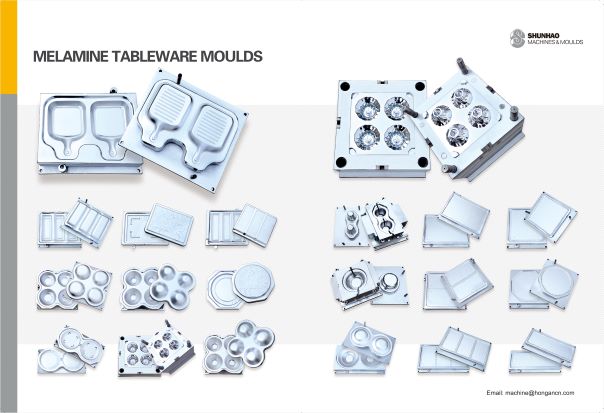

Shunhao moulds factory can make molds: 1. Melamine crockery moulds 2. Urea crockery moulds 3. Glossy melamine moulds 4. Matt finished melamine moulds ...

Shunhao factory has been serving the machines and molds to melamine tableware factories, urea tableware factories, UF toilet seat and cover factories ...

Rice husk tableware Introduction: Rice husk tableware is to regenerate this discarded rice husk into natural, healthy and free of any harmful chemical...

Rationally view the harm of melamine tableware 1) What is melamine tableware Melamine tableware is made from melamine powder (known in the industry as...

Precautions and cleaning of melamine tableware 1. Main ingredients of melamine tableware raw materials: 100% melamine (domestically called A5 material...

The advantages and disadvantages of melamine tableware In daily life, there are many meals used. Tableware is divided into ceramic tableware, bone chi...

Production process of melamine tableware

1. Preheating procedure: Use the raw material box to weigh the tableware to be produced, weigh it, put it into a high-frequency wave to preheat uniformly, and let the powdery raw material block.

2. Plain surface program: Pour the preheated raw materials into the mold, start the mechanical plain surface program, after high temperature and high pressure, curing molding.

3. Decal procedure: cut the flower paper that has been covered with light powder according to the shape of the flower, and paste it on the flat-shaped tableware as required. The flower paper should be pasted properly, the decal orientation is moderate, and it is beautiful and generous. program.

4. Gold adding procedure: After the product is affixed with flowers, evenly spread the light powder on the surface of the product. The light powder should not be sprinkled at least, otherwise it will affect the color of the product, and of course not spread too much. Then start the machine, after mechanical high temperature and high pressure, curing, the surface of the product has the general luster of porcelain

5. Polishing procedure: After the product is produced, it needs to be polished and polished, because the produced product has burrs, which is not conducive to the use of people's lives, and it is easy to cause harm to human hands and mouth; therefore, polishing and polishing are essential. Polishing can remove the burrs of the product, making the product look more beautiful and the edges smoother.

Features of melamine tableware:

Due to the high price of melamine powder, some lawless merchants directly use urea-formaldehyde molding powder as raw materials to produce profits; some use urea-formaldehyde molding powder as raw materials, and then make them in tableware The outer surface is coated with a layer of melamine powder. Tableware made of urea-formaldehyde is harmful to the human body. Yangge melamine tableware experts remind consumers that when buying, they must first go to regular stores and supermarkets, and do n’t be greedy or buy on the stalls; secondly, when buying, it depends on whether the utensils have obvious deformation or color difference. 1. Whether the surface is smooth, whether the bottom is uneven, whether the decal pattern is clear, whether there are wrinkles and bubbles, and the colored tableware is rubbed back and forth with a white napkin to see if there is any discoloration.

Melamine tableware use:

Applicable to: catering (fast food) chain stores, food courts, university (university) canteens, hotels, restaurants, corporate canteens, advertising gifts, etc. Due to the particularity of the molecular structure of melamine plastics, Yangge melamine tableware experts recommend that you do not use melamine tableware in a microwave oven. If it is used, cracking will occur. For the cleaning of melamine plastic tableware, use a soft cloth. Never use rags such as scouring pads and steel balls to clean the surface of tableware, because scouring pads and steel balls will wipe the surface of tableware, making it more susceptible to contamination.

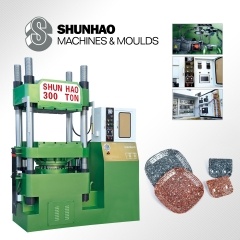

300TONS Single Color Hydraulic Press Melamine Tableware Dinner Set Making Moulding Machine

300TONS Single Color Hydraulic Press Melamine Tableware Dinner Set Making Moulding Machine

Our machine is Suitable for urea tableware, melamine dinnerware.

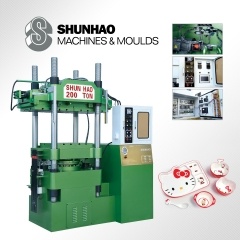

200TONS Automatic Single Color Melamine Tableware Molding Machine

200TONS Automatic Single Color Melamine Tableware Molding Machine

Suitable to be used in the molding operation of urea tableware, melamine tableware

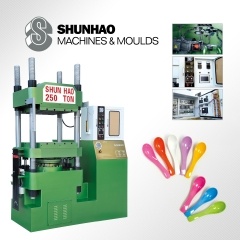

3Year Warantee 250TON Singal Color Melamine Tableware Molding Machine

3Year Warantee 250TON Singal Color Melamine Tableware Molding Machine

Our machine is suitable for all kind of Melamine Dinnerware,plate ,bowl ,tray ,glass ,mug

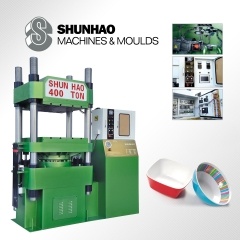

400TON Automatic Melamine Crockery Molding Machine With Singal Color

400TON Automatic Melamine Crockery Molding Machine With Singal Color

Our Machine is special in Melamine Crockery ,like bowl ,plate ,tray ,mug ,glass.

500ton Melamine Crockery Molding Machine With Plc Control

500ton Melamine Crockery Molding Machine With Plc Control

500ton Melamine Crockery Molding Machine With Plc Control For Melamine Tableware ,Melamine Crockery

200Ton 2Color Melamine Tableware Automatic Molding Machine

200Ton 2Color Melamine Tableware Automatic Molding Machine

This machins is Suitable for producing double color melamine tableware, toilet seat cover, Bakelite switches, and mahjong.

Workshop Show

Workshop Show

Products Show

Products Show

Video Show

Video Show

OUR CERTIFICATES

OUR CERTIFICATES

the professional team to service !