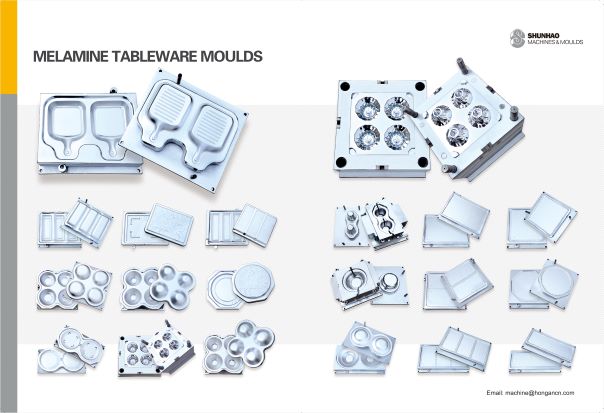

Shunhao moulds factory can make molds: 1. Melamine crockery moulds 2. Urea crockery moulds 3. Glossy melamine moulds 4. Matt finished melamine moulds ...

Shunhao factory has been serving the machines and molds to melamine tableware factories, urea tableware factories, UF toilet seat and cover factories ...

Rice husk tableware Introduction: Rice husk tableware is to regenerate this discarded rice husk into natural, healthy and free of any harmful chemical...

Rationally view the harm of melamine tableware 1) What is melamine tableware Melamine tableware is made from melamine powder (known in the industry as...

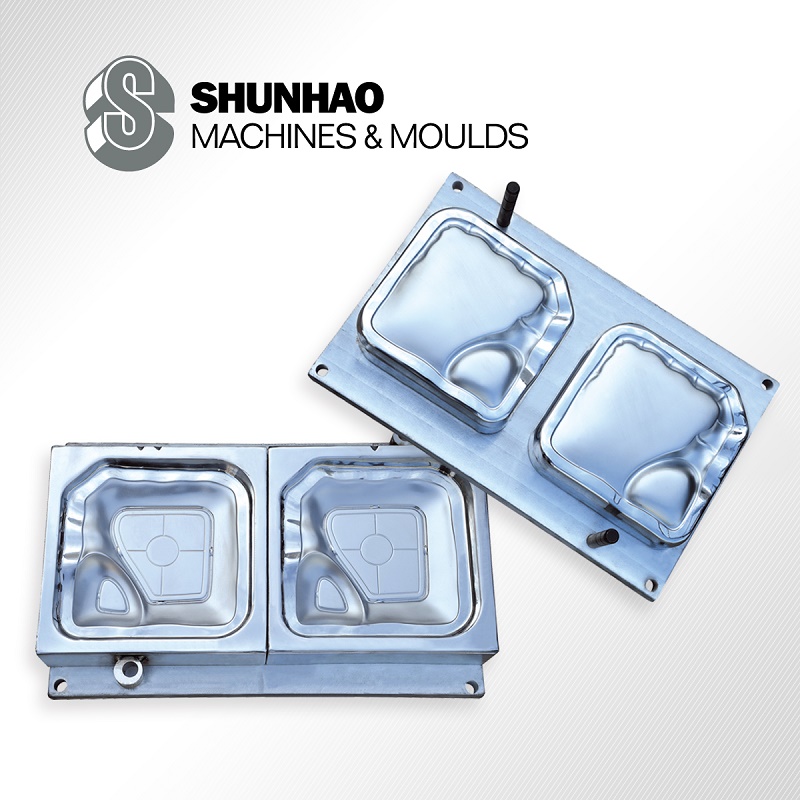

Life of 718H melamine tableware Compress mold

718h mold steel has the same use as P20 mold steel, but because of better hardenability and superior performance, it can produce large-scale, high-grade plastic mold forming parts, which is an advanced plastic mold steel. 718h mold steel hardness can be understood from two aspects.

① Hardening treatment In order to improve the life of the mold to more than 800,000 mold times, it can pre-harden the mold steel. Hardening and low temperature tempering are used to achieve this. During quenching, it is preheated at 500-600 ℃ for 2-4 hours, and then kept at 850-880 ℃ for a certain period of time (at least 2 hours). It is cooled in oil to 50-100 ℃ and air-cooled. The hardness after quenching can reach 50 -52HRC, in order to prevent cracking, a low-temperature tempering treatment at 200 ° C should be immediately performed. After tempering, the hardness can be maintained above 48HRC.

② Nitriding. Nitriding treatment can obtain a high hardness surface layer structure. The hardness of the surface layer after nitriding can reach 650-700HV (57-60HRC). The mold life can reach more than one million times. The nitrided layer has the characteristics of dense structure and smoothness. Improved anti-corrosive performance against humid air and lye.

we are the manufacture of Melamine Tableware Compress Mold in China,if you need any Melamine Tableware Compress Mold,please contact with me.

prev :

What is the difference between 718H mold steel and P20H mold steelnext :

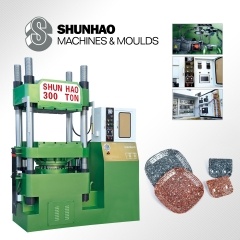

718H steel material properties in melamine crockery mould industrial 300TONS Single Color Hydraulic Press Melamine Tableware Dinner Set Making Moulding Machine

300TONS Single Color Hydraulic Press Melamine Tableware Dinner Set Making Moulding Machine

Our machine is Suitable for urea tableware, melamine dinnerware.

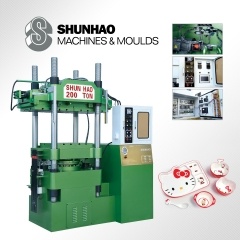

200TONS Automatic Single Color Melamine Tableware Molding Machine

200TONS Automatic Single Color Melamine Tableware Molding Machine

Suitable to be used in the molding operation of urea tableware, melamine tableware

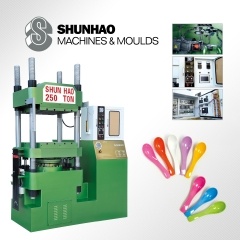

3Year Warantee 250TON Singal Color Melamine Tableware Molding Machine

3Year Warantee 250TON Singal Color Melamine Tableware Molding Machine

Our machine is suitable for all kind of Melamine Dinnerware,plate ,bowl ,tray ,glass ,mug

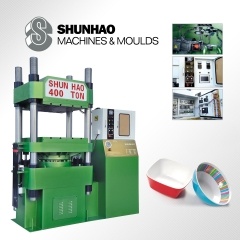

400TON Automatic Melamine Crockery Molding Machine With Singal Color

400TON Automatic Melamine Crockery Molding Machine With Singal Color

Our Machine is special in Melamine Crockery ,like bowl ,plate ,tray ,mug ,glass.

500ton Melamine Crockery Molding Machine With Plc Control

500ton Melamine Crockery Molding Machine With Plc Control

500ton Melamine Crockery Molding Machine With Plc Control For Melamine Tableware ,Melamine Crockery

200Ton 2Color Melamine Tableware Automatic Molding Machine

200Ton 2Color Melamine Tableware Automatic Molding Machine

This machins is Suitable for producing double color melamine tableware, toilet seat cover, Bakelite switches, and mahjong.

Workshop Show

Workshop Show

Products Show

Products Show

Video Show

Video Show

OUR CERTIFICATES

OUR CERTIFICATES

the professional team to service !