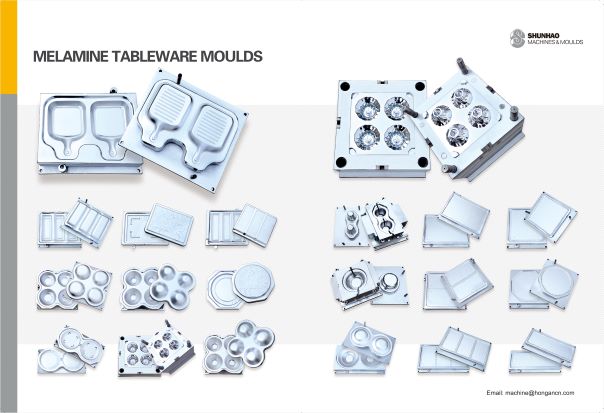

Shunhao moulds factory can make molds: 1. Melamine crockery moulds 2. Urea crockery moulds 3. Glossy melamine moulds 4. Matt finished melamine moulds ...

Shunhao factory has been serving the machines and molds to melamine tableware factories, urea tableware factories, UF toilet seat and cover factories ...

Rice husk tableware Introduction: Rice husk tableware is to regenerate this discarded rice husk into natural, healthy and free of any harmful chemical...

Rationally view the harm of melamine tableware 1) What is melamine tableware Melamine tableware is made from melamine powder (known in the industry as...

item no.:

SHM-300TONSlead time:

20daysproduct orgin:

CHINAbrand:

Shunhaoshipping port:

XIAMENpayment:

TT,LCcolor:

GREENMOQ:

1|

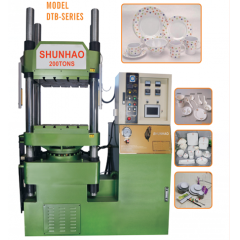

1 Machine name:

|

Melamine Crockery Moulding Machine

|

Melamine Moulding Machine Of Other Brands

|

Notes

|

|

2 Model:

|

Machine model standard

|

Some models are smaller

|

|

|

3 Nominal pressure of main cylinder:

|

Standard

|

Standard

|

|

|

4 Maximum working pressure:

|

Standard

|

Standard

|

|

|

5 Diameter of master cylinder piston:

|

The size of cylinder diameter is standard or larger

|

standard and partially smaller

|

|

|

6 Working stroke of main cylinder:

|

560mm for those above 200T

|

450-550mm for those above 200T

|

|

|

7 Adjustable workbench spacing:

|

Large

|

Large and small

|

|

|

8 Effective working surface:

|

Standard

|

Different standards

|

|

|

11 Tension column (heat treatment grinding)

|

The surface is high temperature and hardened with watermill and plating, and is wear-resisting and polished.

|

The ordinary plating finished surface is not abrasion resistance and easy to be scratched.

|

|

|

12 Oil pressure pumping:

|

Japanese standard series, durable in use

|

Brands selected have poor public reputation at home.

|

|

|

13 Specification of motor:

|

Taiwanese Brand

|

Chinese mainland brand

|

|

|

14 Computer system

|

The low temperature main engine used in Taiwan brand, without high temperature aging and with stable performance, quick response and long service life. The memory card makes program update convenient.

|

Taiwanese Shihlin or Japanese Mitsubishi. The integrated circuit appears high temperature aging easily and faults in breakdown, output, power and connection are frequently happened in the service life of 3-6 years.

|

|

|

15 Oil piping system

|

The newest efficient oil pipe in 2016 with quick response, fast speed and strong stability. The configuration of oil valve is reasonable for convenient and simple maintenance.

|

The oil pipe in 1990 has remained unchanged until 2017, without any progress, which has failed to meet requirements of modern process and output. With ordinary performance, slow action and messy system configuration, the maintenance must be done by skilled labors.

|

|

|

16 Capacity and efficiency

|

The output of the same products in 24 hours is 150 to 200 higher than that of other factories. The conformity rate of finished products reaches 95%.

|

The low output has failed to yield profit for the factory. The factory doesn’t know the yield gap and the backwardness without comparison.

|

|

|

17 Mechanical operation

|

The operational motion is set and the interface integration is simplified. Workers’ training is easy to get started. The various new special functions can deal with more product categories and diversified change of raw materials.

|

The worker training is difficult, due to the multiple setting interfaces. The system operation is basically the same as that one in 1990. No functions are newly increased except for the change of digital readout. It is only a brand without innovation and particularity.

|

The digital readout easily disturbs the computer and causes strange faults. Big error exists between operating position and actual setting. The maintenance cost is high and the installation is simple.

|

|

Name of parts

|

Brand

|

Model

|

Place of origin

|

Notes

|

|

Parts oil cylinder

|

Nodular cast iron

|

FCD-50

|

China, with investment from Taiwan

|

|

|

Master cylinder piston

|

|

White cast iron

|

Domestic

|

|

|

Inlet oil seal

|

NOK

|

|

Japan

|

|

|

PLC host

|

VIGOR

|

|

Taiwan

|

|

|

Pressure module

|

VIGOR 3A

|

|

Taiwan

|

|

|

Human-computer screen

|

FUJI

|

7 inches and colors

|

Japan

|

|

|

Pressure monitor

|

KAVLCO

|

|

Germany

|

|

|

Solenoid valve

|

Victor Taichung

|

|

Taiwan

|

|

|

Oil pressure valve

|

YUTIEN

|

|

Taiwan

|

|

|

Thermometer

|

IDEC-72D

|

|

Taiwan

|

|

|

Motor

|

|

|

Taiwan

|

|

|

Dual pressure pump

|

KEISTER

|

|

Sino-Japanese Joint Venture

|

|

Special notes:

|

||||

|

1. Safety device with photoelectric sensor is added to the machine (comply with the standard configuration of our company).

2. Spare parts are attached to the machine in delivery (comply with the standard configuration of our company).

|

||||

|

|

||||

prev :

200Ton Automatic Hydraulic Press Melamine Moulding Machine For Tableware Dinner Setnext :

300T Automatic Melamine Crockery Moulding Machine From China Melamine Dinnerware Making Machine From Shunhao

Melamine Dinnerware Making Machine From Shunhao

We are the factory of Melamine Dinnerware Making Machine for making trays,bowls,forks,spoons ,mugs,glass.

Single Color Melamine Crockery Compression Machine-MADE IN SHUNHAO

Single Color Melamine Crockery Compression Machine-MADE IN SHUNHAO

We are the factory of melamine tableware compression machine for making trays,mugs,bowls,forks,spoons,ect

2Color Melamine Crockery Moulding Machine From Shunhao

2Color Melamine Crockery Moulding Machine From Shunhao

We are the factory of melamine dinnerware moulding machine for make mugs,glass,forks,spoons,plates,bowls,trays.

Double Color Melamine Tableware Making Machine

Double Color Melamine Tableware Making Machine

We are the factory of melamine tableware making machine for making mugs,spoons,forks,trays,bowls plates,dishes.

Melamine Dinnerware Compression Machine From Shunhao

Melamine Dinnerware Compression Machine From Shunhao

Our machine can be applied in pressing various kinds of melamine dinnerware, such as trays, mugs, plates,chopsticks, spoon, plate, smack-box, starch imitation porcelain tableware plant fiber imitation porcelain tableware, and so on.

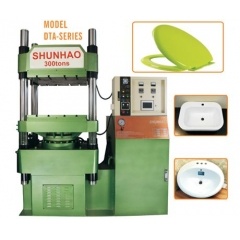

PLC Control Uf/Urea Toilet Seat Cover Compression Machine

PLC Control Uf/Urea Toilet Seat Cover Compression Machine

Various Bakelite Molding Operation,Use for UFC and MDF Toilet Seat cover.

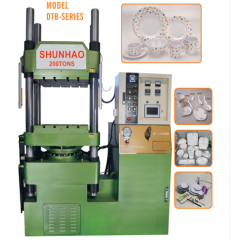

Automatic Single Color Melamine Tableware Compression Machine-MADE IN TAIWAN

Automatic Single Color Melamine Tableware Compression Machine-MADE IN TAIWAN

Melamine hydraulic heating press machine Made In China Suitable for melamine tray, plate, bowl, spoon, cup, mug, ashtray melamine toilet seat, and what kinds.

Workshop Show

Workshop Show

Products Show

Products Show

Video Show

Video Show

OUR CERTIFICATES

OUR CERTIFICATES

the professional team to service !