In this chapter, it is narrative mainly of the 300TONS melamine tableware molding

machine after installation, such as its required preparation, debugging machine, knowing the

main function of the machine. And then it could into production after well debugging. This

step includes the following procedures:

3.1 Preparations before testing

3.2 Horizontal adjustment of machine

3.3 Testing machine

3.1 Preparations before testing

3.1.1 Open sheet metal door and the lid of lubricator of oil tank, and then pour oil into oil tank. Oil level should be in the position of two-thirds of oil gauge.Hydraulic oil used for this machine is 68# oil with feature of wear-resistant and anti-pressed ( 46# hydraulic oil is advised to use if this machine runs under the lower temperature or in winter, to avoid the case of pump failing to suck the oil due to the ropy oil after long time machine no running). If using other types of hydraulic oil, it may reduce working efficiency or increase machine’s fault.

3.1.2 Power: Three phase AC380V, 50HZ (or customerized power).Voltage fluctuation of ±5% is allowed. No need to access to zero line, but need to access to ground line. Three phase power must connect firmly, to avoid burn down the motor due to lack of phase.

3.1.3 Connected to the water cooling. Water volume must be large enough, but not allow the pipeline leakage.

3.1.4 Check whether wiring connection of electric control system is secured;whether there is oil leak phenomenon.

3.1.5 Check each stroke control switch is in the corresponding state.

3.1.6 Check whether there is other things in the heating plate, such as sandstone,iron scraps, tools or if the surface of pillar is clean.

3.1.7 Check whether the settings of pressure, stroke of machine, temperature or related circuit control instrument is correct.

3.1.8 Check the motor running by manual. If reversion, must stop the motor immediately and switch off the power. Changing R-phase of power withT-phase is solved.

3.2 Horizontal adjustment of machine

3.2.1 Separate the big screw nut of guide pillar from upper cover manually, and then separate the big screw nut from cylinder base, the distance is about 100mm to adjust the machine.

3.2.2 Switch on the power, and then adjust the way of operation into “Manual” in the nameplate control panel of electric cabinet.

3.2.3 Without starting the motor, check whether the electric control system is normal;and the valves of oil pipe is installed correctly.

3.2.4. Press on “Second start” button, then the motor starts to run. And then continuously press on the “Second start” button, then the bottom plate ascends slowly. And please stop the motor at the distance of 200-300mm. And then snap the 2 half of the snap rings into the middle of upper piston and groove respectively, and rotate them back until the fix holes aligning with the fix holes

of supporting base, then lock the snap rings by screws (this step could be omitted if the snap rings of piston not removed).

3.2.5 Restart the motor, continuously press on “Second start” to ascend slowly and the 2 plates’ folds together. Then switch off the machine until the upper cover separates from 4 small screws of guide pillar completely. Then lock tightly across the corners of the 4 big screw nuts of the guide pillar on the upper cover manually. Please note that the supporting plate could not be sunk into the screw thread of guide pillar, otherwise, the screw thread will damage the copper bush of holes of the supporting plate.

3.2.6 Continue to slow ascending, to make the 4 small screw nuts of the guide pillar separate from the cylinder base completely, then check whether the distance between the fix screw head of the snap rings of piston and the fix screw head

of oil cylinder is the maximum stroke 400mm.If not 550mm, then continue to slow ascend to reach the max.550mm (the measurement as shown in the figure below). Then stop ascending when reaching 550mm, and lock the 4 big

screw nuts of the guide pillar under the cylinder base with its crossing corner tightly by hand. Please note that the length of the uncovering thread of guide pillar under the cylinder base should be 20-30mm longer than the height of the big nuts.

3.2.7 Make sure that both of the big screw nuts of the upper cover and the oil cylinder have been locked well tightly, and then continue to press on “ Second Start” to slow ascend for compression up to 210kg/cm 2 . If pressure not enough, it could

be adjusted by the pressure regulating valve.

3.2.8 After locking the small screw nuts of the guide pillar tightly by hand, use big hammer or square iron lock well across its corner.

3.2.9 Then decompress and descend the plate, to lock the lock-screws of the big and small screw nuts, to avoid any loosed of the screw nuts.

Warning:

1/Please ascend slowly under the MANUAL status when adjusting the horizontal of machine, only compressing the cylinder piston to keep the best level state of the machine. In the process of adjustment, please use the scale to measure the stroke of the machine, do keep in mind that no more than 550mm, otherwise,the risk happens that the speed cylinder will damage heavily and the piston will

run out of the cylinder and could not press down again. The best stroke range is 500-550mm.

2/When compressing, the pressure should be higher normal use 200kg/c ㎡ but lower than 220KG/C ㎡. After adjustment finished, it must make the pressure regulating valve back to 200KG/C ㎡ to protect this machine.

3/After adjustment, this machine should be in real horizontal level state,

otherwise, it will occur the scratches of the guide pillar and the cylinder (If there is friction of guide pillar or piston, please recalibration the level of this machine).

4/ Lock-screws of screw nuts can not be locked too tight, otherwise, it will deform the screw nuts which could not loose in future.

5/ If need to adjust the upper cover when changing the moulds, first fix the moulds on the down heating plate, and compress slowly the machine under the MANUAL state up to 220KG/C ㎡ ( Do not use the function of “AUTO” or “speed ascend”), then remove the lock-screws of the big and small screw nuts from the guide pillars, and then loosen the small screw nuts of the guide

pillar on the upper cover by big hammer or square iron and separate them from the upper part. And then separate the upper cover from the big screw nuts by slow descend under the MANUAL state. After make the big screw nuts far away from the upper cover, then compress slowly again under MANUAL state to reach the height required, then lock the big screw nuts tightly by hand. And

finally, to compress up to the pressure of 220KG/C ㎡ then hammer on the small screw nuts again.

3.3 Testing machine

3.3.1According to the demand of the production, adjust the distance of slow compression under the MANUAL state (to adjust the correspondent sensor block of the stroke plate on the left of the machine). If it is electrical ruler equipment,then could be set in displace of PLC system (See chapter 4 of electric system).

3.3.2Adjust the related pressure and back pressure of the machine

(1)、Adjust the high-pressure valve: under the state of MANUAL, start the motor, loosen the screw nut of high-pressure adjustment valve, and then stand up to the valve core by the small screwdriver. And then adjust the knob gradually, to make the pressure little higher than 200kg/c ㎡. Finally,lock the screw nut of high-pressure valve tightly.

(2)、Adjust the Medium-pressure valve: under the state of Manual, start the motor, loosen the screw nuts of medium-pressure adjustment valve, and then stand up to the valve core by the small screwdriver. And then adjust the knob gradually, to make the pressure around 40~60kg/c ㎡. Finally,lock the screw nuts of the medium-pressure valve tightly. If it can not

distance during the exhausting under the AUTO state, then add little pressure.

(3)、Adjust the Low-pressure valve: under the state of Manual, start the motor,loosen the screw nuts of Low-pressure adjustment valve, and then stand upto the valve core by the small screwdriver. And then adjust the knob

gradually, to make the pressure around 50~70kg/c ㎡. Finally, lock the screw nuts of Low-pressure valve tightly.

(4)Adjust the Back pressure valve: under the state of Manual, start the motor,loosen the back pressure valve completely. And then press on “First start” and then loose it when the supporting plate fast ascending to the middle of the total stroke. If the supporting plate down then locks tightly the backpressure valve till not down.For the other corresponding valves, please refer to the “Main oil circuit board assembly” of “Oil system” in Chapter 5 or the attached assembly drawing.

3.3.3 According to the production demands, set the parameters in the display of PLC, details please refer to the “Electrical system” in Chapter 4.

3.3.4 Test the machine under the AUTO state.

3.3.5 If any problem causing during testing, such as oil leak in the oil system, or abnormal sound of motor, then please must stop the motor and check.

3.3.6 Switch on the temperature of heating plate, and test the temperature set in the temperature gauge for the heating plate required. The data shown in LCD display is the current temperature of the heating plate. Compare the temperature of heating plate with the setting temperature and find its difference, which difference should be less than ±5°.If it is more than ±5°,

then it must check the heating rods and heating system. Important Notes: A/The pressure must be not more than 220kg/c ㎡ when

adjusting the high pressure, to prevent this machine from overpressure, otherwise, machine must be damaged.B/Please do switch off the power before maintenance or repair when testing this machine, to avoid any electric

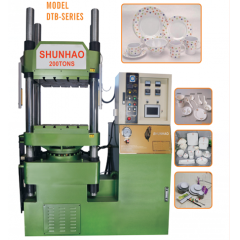

Single Color Melamine Crockery Compression Machine-MADE IN SHUNHAO

Single Color Melamine Crockery Compression Machine-MADE IN SHUNHAO

2Color Melamine Crockery Moulding Machine From Shunhao

2Color Melamine Crockery Moulding Machine From Shunhao

Double Color Melamine Tableware Making Machine

Double Color Melamine Tableware Making Machine

Melamine Dinnerware Compression Machine From Shunhao

Melamine Dinnerware Compression Machine From Shunhao

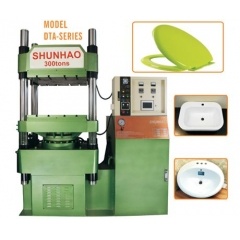

PLC Control Uf/Urea Toilet Seat Cover Compression Machine

PLC Control Uf/Urea Toilet Seat Cover Compression Machine

Automatic Single Color Melamine Tableware Compression Machine-MADE IN TAIWAN

Automatic Single Color Melamine Tableware Compression Machine-MADE IN TAIWAN

Automatic Double Color Melamine Crockery Moulding Machine-MADE IN TAIWAN

Automatic Double Color Melamine Crockery Moulding Machine-MADE IN TAIWAN

Workshop Show

Workshop Show

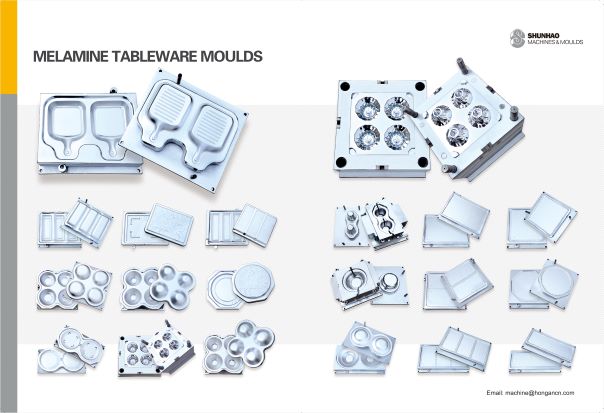

Products Show

Products Show

Video Show

Video Show

OUR CERTIFICATES

OUR CERTIFICATES