Study on Total Migration and Formaldehyde Migration of Melamine Tableware

21 Apr 2020

Study on Total Migration and Formaldehyde Migration of Melamine Tableware

Abstract: By simulating the filling liquid that consumers may use in melamine tableware during daily use, the total migration amount and formaldehyde migration amount are discussed under different soaking liquids, different soaking temperatures, and different soaking times. The value changes. The results show that melamine tableware is relatively unstable under acidic conditions, and both the total migration amount and the formaldehyde migration value are higher. Under cold storage conditions or relatively low temperatures, the values are relatively small, but as the temperature increases, the total migration and formaldehyde migration have increased to varying degrees, and under the action of high temperature of 100 ℃, the formaldehyde migration Leap increase. With the extension of the soaking time, the values of total migration and formaldehyde migration both showed an increasing trend.

According to the statistics of China Plastics Processing Industry Association, the annual output of China's melamine industry reaches 400,000 tons, and the export value of melamine tableware exceeds 1 billion US dollars, accounting for more than 80% of the international market share. From the perspective of development prospects, melamine plastics have more unique advantages in meeting environmental protection and sustainable development requirements than ceramics, bamboo, metal and other products. However, the quality of melamine tableware currently on the market is uneven, and some businesses use cheap urea-formaldehyde to replace melamine formaldehyde resin, and lack of uniform quality specifications, which brings uncertainty to the safety of consumers using melamine tableware factor. The European Union has a relatively complete system standard related to the total migration of food-contact plastics, which stipulates that the total migration limit of food-contact plastics into food is 10mg / dm2, or 60mg / kg, and specifies the detection method when contacting different types of food. This article discusses the value of total migration and formaldehyde migration in different soaking liquids, different soaking temperatures, and different soaking times by simulating the filling liquid that consumers may use to contain melamine tableware in daily use Variety.

1 Materials and methods

1.1 Main materials and reagents

Formaldehyde standard solution, chromotropic acid, glacial acetic acid, absolute ethanol, isooctane, water is distilled water.

1.2 Main instruments and equipment

UV-2550 ultraviolet spectrophotometer, constant temperature water bath, METTLER electronic balance.

1.3 Experimental conditions

1.3.1 Sample processing

First wash the sample to be tested repeatedly with tap water, then rinse with distilled water 2-3 times, air dry, and set aside. Using the filling immersion method, distilled water, 3% acetic acid, 15% ethanol, 95% ethanol, and isooctane were poured into the sample, which was measured after being exposed to a constant temperature of 70 ℃ for 2h.

1.3.2 Experimental operation

(1) Experimental operation of total migration.

Take 200ml of immersion liquid into a glass evaporating dish after constant weight, place the evaporating dish in a water bath and evaporate to dryness, put it in a constant temperature environment of 105-110 degrees for 2h, cool it in a desiccator for 0.5h, weigh it Dry at temperature (100 ± 5) ℃ for 1h, take it out, cool it in a desiccator for 0.5h, weigh it, and perform a blank experiment at the same time.

(2) Experimental operation of formaldehyde migration.

Take 1ml from the soaking solution in a colorimetric tube with stopper, add 1ml of chromotropic acid solution and 8ml of 75% sulfuric acid solution, put it in a 60 ° C water bath for 20 minutes, then go to the machine for measurement and carry out a blank experiment. At the same time, standard working curves of five concentrations of 0, 5, 10, 20, 30mg / kg and so on are made.

2 Results and analysis

2.1 Test results of different soaking solutions

It can be seen from Tables 1 and 2 that distilled water, 15% ethanol, 95% ethanol, and isooctane are used as simulated immersion fluids. Both the total migration value and the formaldehyde migration value are relatively small, and there is not much difference between them. However, the data of 3% acetic acid immersion is obviously higher. It means that under acidic conditions, the light powder layer on the surface of the tableware is more likely to be destroyed, so that under high temperature conditions, the resin that has not been polymerized will dissolve, resulting in a higher value in both the total migration amount and the formaldehyde migration amount. Therefore, the choice of 3% acetic acid as the soaking solution can be considered as a strict condition.

2.2 The effect of different immersion temperature on the result

Choose 3% acetic acid as the soaking solution, soak for 4 hours under the temperature conditions of 40, 60, 70 and 100 for 2 hours to analyze the effect of different soaking temperature on the total migration and formaldehyde migration.

It can be seen from Table 3 and Table 4 that the soaking temperature has a great influence on the total migration and formaldehyde migration in melamine tableware. The value is relatively small under cold storage conditions or relatively low temperatures, but as the temperature increases, the two The numerical values of the items have different degrees of change, and under the action of high temperature of 100 ℃, the migration of formaldehyde has shown a dramatic increase. This is because melamine and formaldehyde resins are very unstable, especially at high temperatures, its structure is likely to change, releasing melamine molecules and formaldehyde monomers. Therefore, if you often put inferior melamine plastics containing food in a microwave oven for heating, the risk is very high. In addition, melamine plastics may also release formaldehyde, which is more harmful to children.

2.3 The effect of different soaking time on the result

According to the EU Directive, three migration experiments are required for the formaldehyde migration of tableware exported to Europe, and the last soaking solution is taken as the measuring solution to determine the value of the formaldehyde migration of the sample. Therefore, this experiment also carried out three migration tests on the same sample. The condition was 70 ° C for 2h, and three migration experiments were conducted. 〖JZ〗 Table 5 Effect of soaking time on total migration

As can be seen from Table 5 and Table 6, as the immersion time is extended, the values of total migration and formaldehyde migration both show an increasing trend. Analyze the reason. The finished melamine is a thermosetting plastic. When the immersion time is longer at 70 ℃, some crosslinks in its internal structure are separated, so that the formaldehyde monomer migrates into the immersion liquid.

3 Conclusion

The above three experiments prove that melamine tableware is relatively unstable under acidic conditions, and the total migration amount and formaldehyde migration value are higher. Under cold storage conditions or relatively low temperatures, the value is relatively small, but with the increase of temperature, the total migration and formaldehyde migration have increased to varying degrees, and under the action of high temperature of 100 ℃, formaldehyde migration Leaping increase. With the extension of the soaking time, the total migration amount and the migration amount of formaldehyde both showed an increasing trend. This shows that when we use melamine tableware, as the number of uses increases, the light powder layer on the surface is gradually destroyed. Furthermore, the internal cross-link bonds are broken, so that some harmful substances are released into the tableware filling.

Therefore, consumers should pay attention to the following points when purchasing and using products and use

①Only enterprises that have obtained food and product quality and safety production licenses can produce melamine tableware. All qualified melamine tableware in their production and processing must be marked with a quality and safety production license number uniformly formulated by the state before sales, and printed at the same time. Or affix the quality and safety market access mark QS;

② Melamine tableware can not be used in the microwave oven, if it is used, it will crack, which will affect the life of the tableware;

③ For the cleaning of melamine plastic tableware, use a soft rag. Never use rags such as scouring pads and steel balls to clean the surface of the tableware. It is more susceptible to contamination.

Therefore, consumers should pay attention to the following points when purchasing and using products and use

①Only enterprises that have obtained food and product quality and safety production licenses can produce melamine tableware. All qualified melamine tableware in their production and processing must be marked with a quality and safety production license number uniformly formulated by the state before sales, and printed at the same time. Or affix the quality and safety market access mark QS;

② Melamine tableware can not be used in the microwave oven, if it is used, it will crack, which will affect the life of the tableware;

③ For the cleaning of melamine plastic tableware, use a soft rag. Never use rags such as scouring pads and steel balls to clean the surface of the tableware. It is more susceptible to contamination.

As the quality supervision department, it should increase the promotion of melamine tableware manufacturing and use safety, improve safety awareness, standardize the label, and constantly improve China's melamine tableware safety evaluation system; in addition, improve the detection ability, increase supervision, and strictly eliminate unqualified Products flow into the market, infringing on the personal safety of consumers.

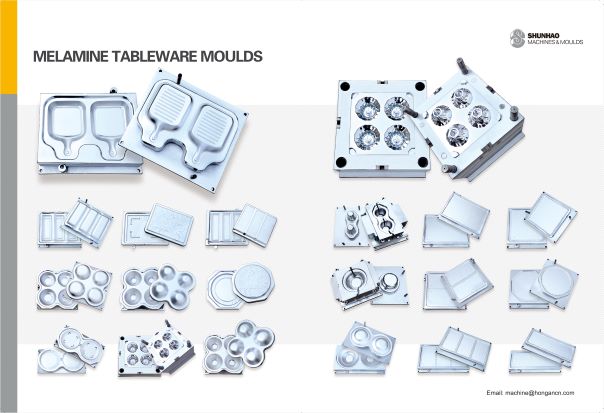

We are the manufacturer of Melamine Plate Molds,Melamine Bowl Molds,Melamine Spoon Molds,Melamine Fork Molds,Melamine Mug Molds,if you need Melamine Molds,Please contact with me,thanks!

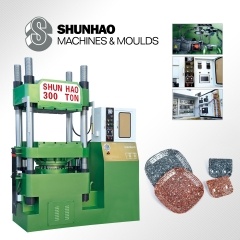

300TONS Single Color Hydraulic Press Melamine Tableware Dinner Set Making Moulding Machine

300TONS Single Color Hydraulic Press Melamine Tableware Dinner Set Making Moulding Machine

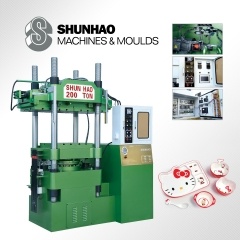

200TONS Automatic Single Color Melamine Tableware Molding Machine

200TONS Automatic Single Color Melamine Tableware Molding Machine

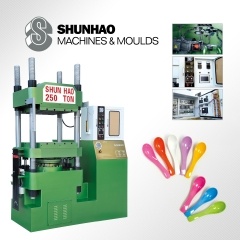

3Year Warantee 250TON Singal Color Melamine Tableware Molding Machine

3Year Warantee 250TON Singal Color Melamine Tableware Molding Machine

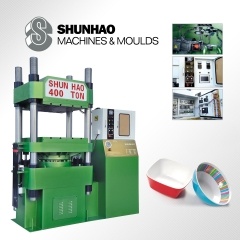

400TON Automatic Melamine Crockery Molding Machine With Singal Color

400TON Automatic Melamine Crockery Molding Machine With Singal Color

500ton Melamine Crockery Molding Machine With Plc Control

500ton Melamine Crockery Molding Machine With Plc Control

200Ton 2Color Melamine Tableware Automatic Molding Machine

200Ton 2Color Melamine Tableware Automatic Molding Machine

Workshop Show

Workshop Show

Products Show

Products Show

Video Show

Video Show

OUR CERTIFICATES

OUR CERTIFICATES