categories

recent posts

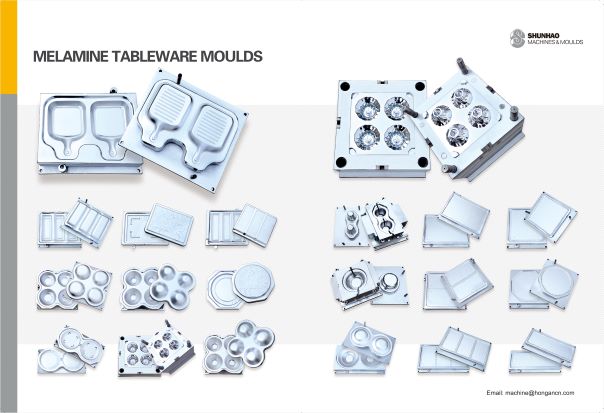

Shunhao moulds factory can make molds: 1. Melamine crockery moulds 2. Urea crockery moulds 3. Glossy melamine moulds 4. Matt finished melamine moulds ...

Shunhao factory has been serving the machines and molds to melamine tableware factories, urea tableware factories, UF toilet seat and cover factories ...

Rice husk tableware Introduction: Rice husk tableware is to regenerate this discarded rice husk into natural, healthy and free of any harmful chemical...

Rationally view the harm of melamine tableware 1) What is melamine tableware Melamine tableware is made from melamine powder (known in the industry as...

Precautions and cleaning of melamine tableware 1. Main ingredients of melamine tableware raw materials: 100% melamine (domestically called A5 material...

The advantages and disadvantages of melamine tableware In daily life, there are many meals used. Tableware is divided into ceramic tableware, bone chi...

Fully degradable plant fiber cutlery is produced in the tide of protecting the environment, treating white pollution, replacing polystyrene foam tableware (EPS). The research and development of this production technology is mainly in China. There are few reports abroad and it has obvious Chinese characteristics. This is because China's timber resources are scarce, but bamboo, reeds, and agricultural crops such as citrus stems, rice straw, rice straw, and other herbal fiber or bagasse, sawdust and other waste are very rich natural resources formed. After these raw materials are pretreated by pulverization and the like, and the additives such as adhesives, water-resistant agents, fillers, etc. that meet food hygiene standards are hot-press-molded under a certain process, a fully decomposed vegetable fiber molded tableware can be obtained. .

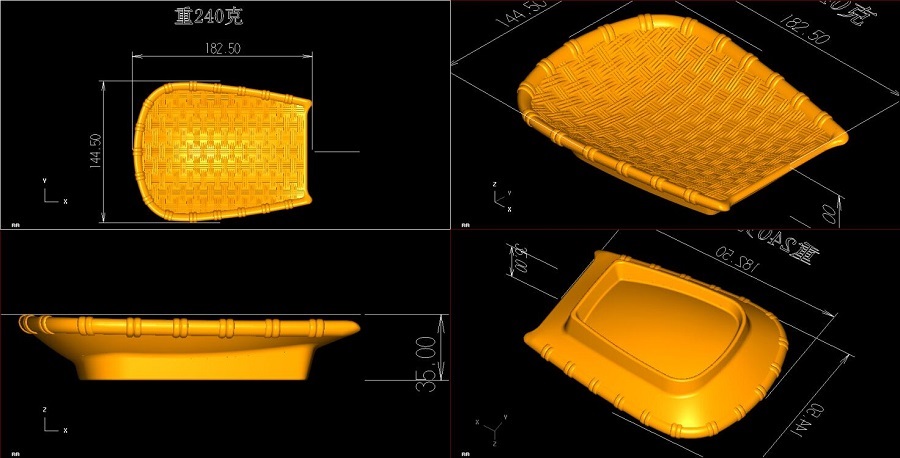

Bamboo Powder Dinnerware Mold

The full-degradation plant fiber tableware was developed in China in the early 1990s, and it has been developed in the country in the late 1990s. By the end of 1999, there were about 50 production lines for production completed in China, and the output was 2 billion; in recent years, the relevant manufacturers and Scientific research workers have successively overcome defects in appearance, strength, and shortcomings in hot brittleness, and in particular achieved breakthroughs in moisture-proof, mildew-proof and health indicators; at the same time, the developed process equipment is miniaturized, the production efficiency is high, and the price is low. Increasingly mature, product quality meets GB18006.1-1999 "one-time degradable tableware with general technical conditions" requirements. Some products have been exported to Korea and Southeast Asia and are making positive contributions to the environmental protection of our country and the world.

1. Advantages and main problems of vegetable fiber cutlery Among the five alternatives of biodegradable plastic cutlery, PE coated cardboard cutlery, pulp molded cutlery, vegetable fiber molded cutlery, and starch molded cutlery that currently replace EPS cutlery, Plant fiber molding meal has two prominent advantages:

Vegetable fiber Tableware Mould

The first is the advantage of resources. It does not consume wood at all, and its sources of materials are extensive and abundant. All of them are renewable resources, which are very suitable for China's national conditions of resources and can reduce its length;

The second is the environmental advantages. It has good self-degradation performance, it does not need to carry out large-quantity recycling, and is self-contained in the environment. It can be eroded into soil by soil. Under certain raw material components, it can also be used as food for fish and poultry. It is the most environmentally friendly tableware. However, due to the acquisition and performance of raw materials, there are some problems that need to be seriously solved in such dishes:

1 Residues of pesticides, feces, dust, and bacterial molds attached to the fibers of agricultural crops raise concerns that it is difficult to ensure safety and hygiene in large-scale production;

2 easier to absorb moisture, may be mild in wet environments;

3 Poor flexibility, so that the drop strength is poor; In the hot water hot oil state, the adhesive strength is poor, brittle, hand-side force, the product is easy to break;

Degradable tableware mold

4 The appearance is rough, the color is yellow;

5 Because the raw materials are not flexible and brittle, the walls of finished cutlery products are thicker and have larger unit weights, which affects the transportation costs.

2. Production process The production process of vegetable fiber tableware can be divided into eight parts: selection of main materials, main material pretreatment, batch mixing, measurement and weighing, hot press forming, surface spraying, drying and disinfection, and packaging storage. .

prev :

Why buy Auto Melamine Dinnerware Grinding Machinenext :

Imitation porcelain tableware on the knowledge 300TONS Single Color Hydraulic Press Melamine Tableware Dinner Set Making Moulding Machine

300TONS Single Color Hydraulic Press Melamine Tableware Dinner Set Making Moulding Machine

Our machine is Suitable for urea tableware, melamine dinnerware.

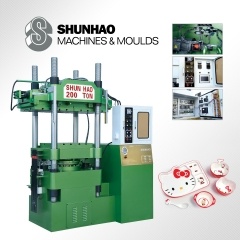

200TONS Automatic Single Color Melamine Tableware Molding Machine

200TONS Automatic Single Color Melamine Tableware Molding Machine

Suitable to be used in the molding operation of urea tableware, melamine tableware

3Year Warantee 250TON Singal Color Melamine Tableware Molding Machine

3Year Warantee 250TON Singal Color Melamine Tableware Molding Machine

Our machine is suitable for all kind of Melamine Dinnerware,plate ,bowl ,tray ,glass ,mug

400TON Automatic Melamine Crockery Molding Machine With Singal Color

400TON Automatic Melamine Crockery Molding Machine With Singal Color

Our Machine is special in Melamine Crockery ,like bowl ,plate ,tray ,mug ,glass.

500ton Melamine Crockery Molding Machine With Plc Control

500ton Melamine Crockery Molding Machine With Plc Control

500ton Melamine Crockery Molding Machine With Plc Control For Melamine Tableware ,Melamine Crockery

200Ton 2Color Melamine Tableware Automatic Molding Machine

200Ton 2Color Melamine Tableware Automatic Molding Machine

This machins is Suitable for producing double color melamine tableware, toilet seat cover, Bakelite switches, and mahjong.

Workshop Show

Workshop Show

Products Show

Products Show

Video Show

Video Show

OUR CERTIFICATES

OUR CERTIFICATES

the professional team to service !