categories

recent posts

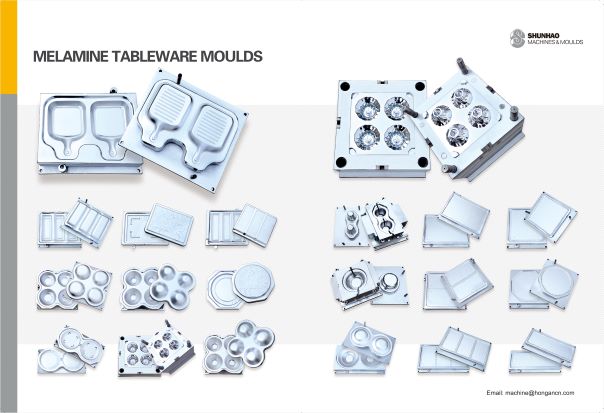

Shunhao moulds factory can make molds: 1. Melamine crockery moulds 2. Urea crockery moulds 3. Glossy melamine moulds 4. Matt finished melamine moulds ...

Shunhao factory has been serving the machines and molds to melamine tableware factories, urea tableware factories, UF toilet seat and cover factories ...

Rice husk tableware Introduction: Rice husk tableware is to regenerate this discarded rice husk into natural, healthy and free of any harmful chemical...

Rationally view the harm of melamine tableware 1) What is melamine tableware Melamine tableware is made from melamine powder (known in the industry as...

Precautions and cleaning of melamine tableware 1. Main ingredients of melamine tableware raw materials: 100% melamine (domestically called A5 material...

The advantages and disadvantages of melamine tableware In daily life, there are many meals used. Tableware is divided into ceramic tableware, bone chi...

The main advantages of high-speed machining are:

High-speed processing of high precision, surface quality, high production efficiency, the application in the mold industry is very effective, the traditional electric processing technology can not match, fully in line with modern manufacturing technology, "high efficiency, high precision and high degree of automation "The direction of development, has broad application prospects.

we are the manufacturer of melamine mould,melamine tableware mould,melamine crockery mould,melamine dinnerware mould in China,more information at http://melaminemould.com

prev :

Five reasons to choose the five big reason the melamine tablewarenext :

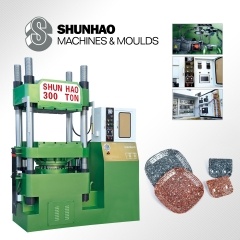

Mold manufacturing process how to determine the parting line? 300TONS Single Color Hydraulic Press Melamine Tableware Dinner Set Making Moulding Machine

300TONS Single Color Hydraulic Press Melamine Tableware Dinner Set Making Moulding Machine

Our machine is Suitable for urea tableware, melamine dinnerware.

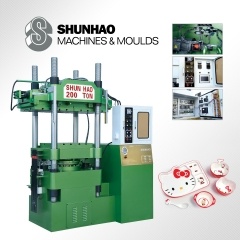

200TONS Automatic Single Color Melamine Tableware Molding Machine

200TONS Automatic Single Color Melamine Tableware Molding Machine

Suitable to be used in the molding operation of urea tableware, melamine tableware

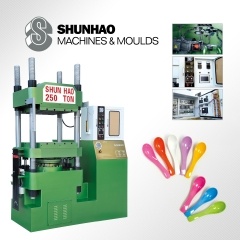

3Year Warantee 250TON Singal Color Melamine Tableware Molding Machine

3Year Warantee 250TON Singal Color Melamine Tableware Molding Machine

Our machine is suitable for all kind of Melamine Dinnerware,plate ,bowl ,tray ,glass ,mug

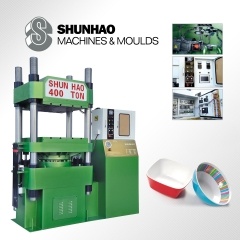

400TON Automatic Melamine Crockery Molding Machine With Singal Color

400TON Automatic Melamine Crockery Molding Machine With Singal Color

Our Machine is special in Melamine Crockery ,like bowl ,plate ,tray ,mug ,glass.

500ton Melamine Crockery Molding Machine With Plc Control

500ton Melamine Crockery Molding Machine With Plc Control

500ton Melamine Crockery Molding Machine With Plc Control For Melamine Tableware ,Melamine Crockery

200Ton 2Color Melamine Tableware Automatic Molding Machine

200Ton 2Color Melamine Tableware Automatic Molding Machine

This machins is Suitable for producing double color melamine tableware, toilet seat cover, Bakelite switches, and mahjong.

Workshop Show

Workshop Show

Products Show

Products Show

Video Show

Video Show

OUR CERTIFICATES

OUR CERTIFICATES

the professional team to service !