1:Adopts 4 guide-pin with well-grind heat-treatment and the latest

Japnese Yuken double proportional valve control system,be able to variable

adjustment of speed and pressure,this machine designs for diversification

products and well-required action and high accuracy of machine,wear-resistance

and durable

2:Able to own-set according to the depth of

products,fast-low speed of pressing material,infinite set of moving mold speed

and action,different molds with different adjustment,stable running,high

accuracy,to keep molds safe

3:Automatic operation after running action

setting,with 2types of single color and double color products production.

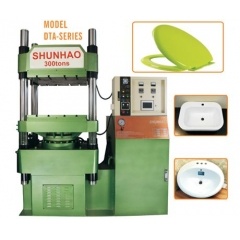

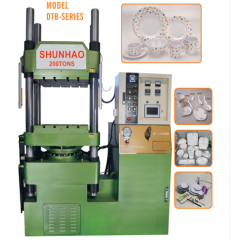

4:Suitable for producing:double color melamine

products,toilet seat cover,Bakelite switches,mahjong and the s-products with

3-dimensions which could not open vertically but horizontally

1.Before operation the machine, supply the power and check if the motor rotation direction is

correct.

2. Make machine to run in “Manual way”during operation, ascend the machine slowly. Install the

nuts and lock with screw for all the 4 pillars. And then descend the machine to make the nuts to

meet its right place.

3.After locking the nuts, use the hammer to lock tightly byAnti-clockwise derection.

4. Correction of the parallel of the heating plate: firstly ascend the screw nuts of upper heating

plate, and then ascend the machine, to seperate the upper heating plate from the screw nuts, but do

not touch. And then combine the screw nuts 1 and 2 together. Then pressure the machine by

230kg/cm 2 to lock the screw nuts tightly by anti-clockwise direction.

Preparation before machines operation

I.Hydraulic oil supply: 70% of hydraulic device failure is causing by the improper hydraulic oil

using. In addition to the ability of the high compression, even under low temperature high

pressure easy flow, good hydraulic oil also requires the following features:

A. Good viscosity;

B. Long time stability (no physical or chemical changes)

C. Oxidation stability ( no promote rust and corrosion)

D. Able to fast separation and precipation of the foreign matters (Anti-emulsibility and

defoaming)

E. Good lubricity

F. Suitable for various materials of oil seal

G. Less display and good fire-resistance

H. No-toxic

This machine use SHEEL-46, cycle oil with high-performance hydraulic oil. Feeding oil from the

filler back of machine, different capacity of oil tank with different models of machines. To fill in

the oil, not higher than 80% of the height.

(II)Testing of motor pump:

After feeding the hydraulic oil, check the running direction of the motor pump. Now turn on the

Control button under Manual from the panel, and start the motor switch. During motor running,

test it some rolls then ok. If the motor rotation direction oppsite the direction of arrow marked,

then reverse connection of any 2 pcs of power wires out of 3.

(III) OPEN CIRCULATING OF COOLING WATER:

Before running machine, firstly open the cirluating cooling water, to keep the oil temperature

(I) INTRODUCTION:

In order to increase production efficiency, it may longer the mechanical operation time, which

may one day nearly 24 hours of production. In terms of the 25days per month of operation to

count the cumulative monthly production operations to 600 hours, so a year will be 7200 hours.

To compareother general machine tools, it is 4-5 times the length of operating time, hence,

hydraulic machine maintenance must pay more attention than the average of the production

machinery industry.

1. Maintenance and Inspection:

1). Inspection before operation:

A. Check the hydraulic oil capacity: checking the fuel gauge, to determain whether the oil tank

save more than 80% or 70% or less than 70%;

B. Check the Emergency Stop switch: Any emergency situation must be stopped in case of

operation, immediately press the Emergency stop switch, the machine is able to stop running (if

only press the motor stop switch is invalid) in an instant.

C. Check the apparatus of Slow-speed mold open: Determine whether the gap between the upper

and lower mold adhesion, whether the force of each pillar of the state average.

D. Check all the movable parts: Any movable parts need to be properly lubricated, and clean dirts

out of these movable parts, to keep the machine running well. Main axis of this machine equips

with lubricating bearings, no required extra lubricated agents.

E. Check the cooling water system: To check all the cooling water pipes are not leaking and make

sure the enough water to keep the normal running. Under normal production ( not 3 shifts), the

case of insufficient water or completely interrupted, can continuously run 4-8 hours without

cooling, no any damage to operate this machine.

F. Suvaillance ofAbnormal sound: such as hydraulic pump, solenoid valves, relay, etc. Abnormal

sound, to prevent any damage to the machine.

G. Check the accuracy of the micro-switches: in order to determain precise entire automation

cycle operation. Order bit of the action in particular need to adjust and position locate, especially

the molds.

2) Every day checking and maintenance:

A. Daily operations, should be dry cloth to gently wipe the surface of the machine ministries and

electrical control box glass.

B. Remove trivial and dust from the heating plate.

C. Such as abnormal sound happen during operation, should immediately check and solve.

D. Clean all around the machine.

E. Switch off power and release the press of oil gauge as ZERO.

3). Every week checking and maintenance:

A. Check the eletric heaters: to check heater ampere pointer whether flexible and normal; check

whether broken line or loose wiring, etc.

B. Check the oil-leak: to check all the connecters of the hydraulic circuit or pipes whether there is

oil leak stain; even if little oil-leak, it should also be noted.

C. Check the tightness of screw and nuts: To ensure accuracy of mechanical assembly, preventing

from displacement loosening.

D. Check the height of the oil gauge of oil tank.

4). Every month checking and maintenance:

A.Clean the grease filter, replace damaged

B. Check the basement of the machine is loose or displaced

C. Check the levelness machinery

D. Check the switch common abnormality of arcing

5).Yearly maintenance:

A. Clean the oil tank

B. Re-fill the new oil

2. MACHINE OPERATION:

This machine is fully automatic operation (AUTO), “MANUAL” only use for placing molds or

mold testing or other special cases. Hereby method of operation as below:

A. Manual operation ( Mold trial or placing molds using):

Select the switch under Manual position, the cylinder ascend or descend manually, to meet the

manual or adjustment requirement.

B.Auto operation ( Normal productin using):

Select the switch under AUTO position, this machine will be operated automatically.

3. Security codes:

A. During operation of the machine except when necessary, should try not to develop a hand as an

aid operation.

B. Memorize the position of the emergency stop switch.

C. The worker should wear short-sleeved or sleeveless tight clothes, especially avoid wide sleeves

dragon costumes.

D. If necessary view, should be first stop and then view.

E. Troubleshooting should be an expert or technician whom.

F. Keep the surrounding environment clean, traces of oil in particular should prevent any

inadvertent from ground.

G. In case when a large number of oil spill stains the ground, first wiped with a lot of grease, then

the ground can be slippery layer of sawdust or salt, lime to prevent slippery.

Machine operation and Trouble shooting

Eletric circuit troubleshooting:

The company uses 1-on-1 circuit wiring methods, namely electrical box microcomputer

input signal and the output signal has its own name, and have their own features and lights,

so just check each respective signal lights in the trigger, whether lighting, electrical

components to confirm whether it is normal or damaged, the following example:

Input signal:

1. Press “MOTOR START”, then No.4 light upper line of PLC should work; If not light,

then check whether it is under Manual way or the button is damaged or broken off wire;

2. Take a iron bar before (Rising limited) approching switch, then No.17 light of PLC

should work; If not light, change the approching swtich or check the X17 wire broken off.

◎Input signal: PLC output, because of its lower resistance - current, first start the relay

and then use relay to start hydraulic valves or eletromagnetic contactor.

Note: PLC lower part is LX voltage (relay coil is DC24V), R on the relay

board and Y0-Y12 isAC220V, DO NOT connect “COM” with Y0-Y12.

The following is a description of the input and output signals:

X0 L-MOLD MANUAL/AUTO Y0 L-MOLD MOTOR

X1 L-MOLD RESIN MOLDING START

/MAUNAL FAST-DOWN SWITCH

Y1 L-MOLD DOWN-VALVE

X2 L-MOLD PATTERN START SWITCH Y2 L-MOLD UP- VALVE

X3 L-MOLD FINISHING AGENT START

SWITCH

Y3 L-MOLD CORE-LOOSE 3

X4 L-MOLD MOTOR START SWITCH Y4 L-MOLD CORE-LOOSE 3

X5 L- MOLD MOLD RETURN SWITCH Y5 L-MOLD L-PRESSURE VAVLE

X6 L-MOLD MANUAL FAST-DOWN SWITCH Y6 L-MOLD PRESSURING VALVE

X7 L-MOLD MANUAL FAST-UP SWITCH Y7 L-MOLD RELIEF VALVE

X10 L-MOLD MANUAL LOW-DOWN SWITCH Y10 L-MOLD EXAUSTING VALVE

X11 L-MOLD MANUAL LOW-UP SWITCH Y11 L-MOLD PREFILL VALVE

X12 L-MOLD 1 CYLINDER BACK Y12 L-MOLD BACK VALVE

X13 L-MOLD 1 CYLINDER FORWARD Y13 L-MOLD MOLDING TIME

X14 L-MOLD EMERGENCY STOP Y14 L-MOLD CORE-LOOSE 1

X34 L-MOLD 2 CYLINDER BACK Y15 L-MOLD CORE-INSERT 1

X35 L-MOLD 2 CYILNDER FORWARD Y16 L-MOLD CORE-LOOSE 2

X40 L-MOLD 3 CYLINDER BACK Y17 L-MOLD CORE-INSERT 2

X41 L-MOLD 3 CYLINDER FORWARD

X44 L-MOLD CORE-INSERT START

R-MOLD INPUT X R-MOLD OUTPUT Y

X15 R-MOLD MANUAL /AUTO Y20 R-MOLD MOTOR

X16 R-MOLD STAYLIMITD RESIN

MOLDING START SWITCH

Y21 R-MOLD DOWN VALVE

X17 R-MOLD UP-LIMITED/EMERGENCY

STOP/PATTERN START SWITCH

Y22 R-MOLD UP-VALVE

X20 R-MOLD FINISHING START SWITCH Y23 R-MOLD CORE-LOOSE 3

X21 R-MOLD MOTOR START SWITCH Y24 R-MOLD CORE-INSERT 3

X22 R-MOLD MOLD BACK Y25 R-MOLD L-PRESSURE VALVE

X23 R-MOLD MANUAL FAST-DOWN Y26 R-MOLD PRESSURING VALVE

X24 R-MOLD MANUAL FAST-UP Y27 R-MOLD RELIEF VALVE

X25 R-MOLD MANUAL SLOW-DOWN Y30 R-MOLD EXAUSTING VALVE

X26 R-MOLD MANUAL SLOW-UP Y31 R-MOLD PREFILL VALVE

X27 R-MOLD 1 CYLINDER BACK Y32 R-MOLD BACK VALVE

X30 R-MOLD 1 CYLINDER FORWARD Y33 R-MOLD MOLDING TIME

X31 R-MOLD EMERGENCY STOP Y34 R-MOLD CORE-LOOSE 1

X36 R-MOLD 2 CYLINDER BACK Y35 R-MOLD CORE-INSERT 1

X37 R-MOLD 2 CYLINDER FORWARD Y36 R-MOLD CORE-INSERT 2

X42 R-MOLD 3 CYLINDER BACK Y37 R-MOLD CORE-INSERT 2

X43 R-MOLD 3 CYLINDER FORWARD

X45 R-MOLD CORE-INSERT START

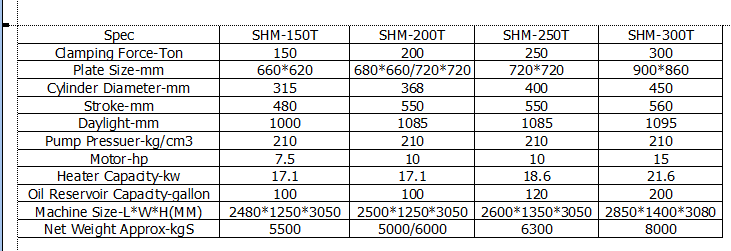

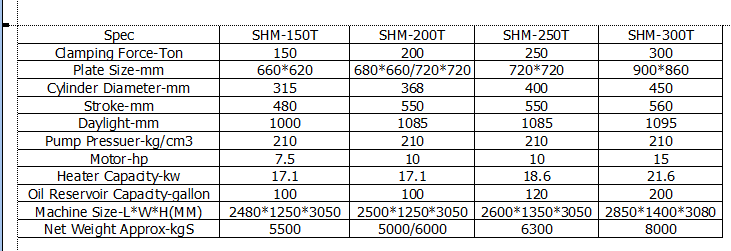

we are the factory of Melamine Tableware Compres Machine,Melamine Dinerware Compressing Machine,Melamine Crockery Compressing Machine,more information at http://www.melaminemould.com/melamine-compression-machine_sp

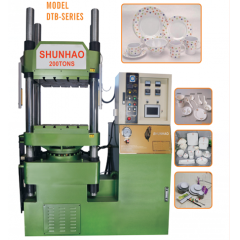

Melamine Dinnerware Making Machine From Shunhao

Melamine Dinnerware Making Machine From Shunhao

Single Color Melamine Crockery Compression Machine-MADE IN SHUNHAO

Single Color Melamine Crockery Compression Machine-MADE IN SHUNHAO

2Color Melamine Crockery Moulding Machine From Shunhao

2Color Melamine Crockery Moulding Machine From Shunhao

Double Color Melamine Tableware Making Machine

Double Color Melamine Tableware Making Machine

Melamine Dinnerware Compression Machine From Shunhao

Melamine Dinnerware Compression Machine From Shunhao

PLC Control Uf/Urea Toilet Seat Cover Compression Machine

PLC Control Uf/Urea Toilet Seat Cover Compression Machine

Automatic Single Color Melamine Tableware Compression Machine-MADE IN TAIWAN

Automatic Single Color Melamine Tableware Compression Machine-MADE IN TAIWAN

Workshop Show

Workshop Show

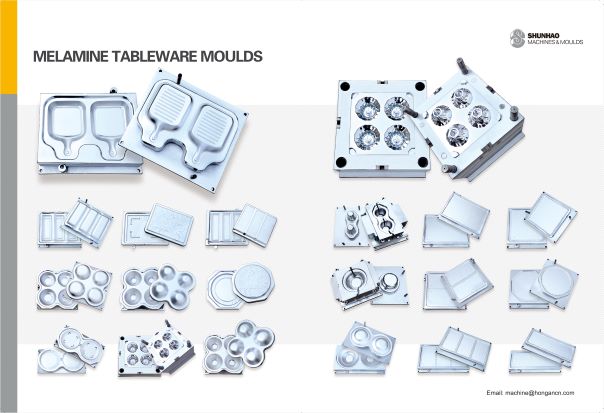

Products Show

Products Show

Video Show

Video Show

OUR CERTIFICATES

OUR CERTIFICATES